Meet the Maker: Tom Lipton

World-class machinist Tom Lipton was given the option to produce one of three different parts for Project Egress. His choice was a very personal one, connecting to a decision he made in 1987 that changed his future.

World-class machinist Tom Lipton was given the option to produce one of three different parts for Project Egress. His choice was a very personal one, connecting to a decision he made in 1987 that changed his future.

Read on to learn why this project is so personal to Tom. (And yes, of course his part is fully functional. This is Tom Lipton, after all.)

Bio: Tom Lipton AKA Oxtoolco or sometimes even Mr Bozo is a lifelong metalworker. During the day Tom is on the cutting edge of science at Lawrence Berkeley National Lab providing technical solutions to scientists involved in fundamental research advancing human knowledge and building solutions to problems facing all humans. In an effort to preserve and advance trade knowledge and skills Tom has also authored two books on metalworking and engineering subjects as well as built a large metalworking following as Oxtoolco on YouTube. Tom is extremely passionate about the skilled trades that have provided him with such a rewarding career. This passion for the work permeates his life and the people he surrounds himself with. This extends to his personal life where he is more likely to be found in his workshop at home happily working away than anywhere else. Tom also holds six United States Patents for unique devices and has designed an array of equipment for the consumer product testing, laboratory equipment, medical devices and machine tool industries. He lives with his beloved wife and pesky dog in the San Francisco Bay area.

Artist Statement: “When I was a kid growing up in California I remember going outside in the summer of 1969, looking up facing as close to east as I could, straining to catch a glimpse of the mighty Saturn booster carrying Apollo 11 as it lifted off. The rest of the family was back in the house watching the launch on an old black and white television. I had asked my dad which way Florida was so I could look in the right direction. At 8 years old I didn’t know that there was a slim to none chance I would be able to see the Saturn V blasting off on its way to the moon landing. This illustrates how focused the country was on the space program. Everybody was talking about it and felt like they were a part of the national effort to put a man on the moon. Kids didn’t want to be hedge fund managers, they wanted to be astronauts.

Fast forward to around 1987. At the time I was working as a welder machinist along with one of my great machining mentors. In the sweltering summer of the south I found myself in the Louisville, Kentucky, area on travel assignment for a special project. Exploring the local area on my time off I happed to visit the Kentucky science and technology center. I might not have gone there but my first choice was the Louisville Slugger factory tour which was jam packed so fate presented my alternate.

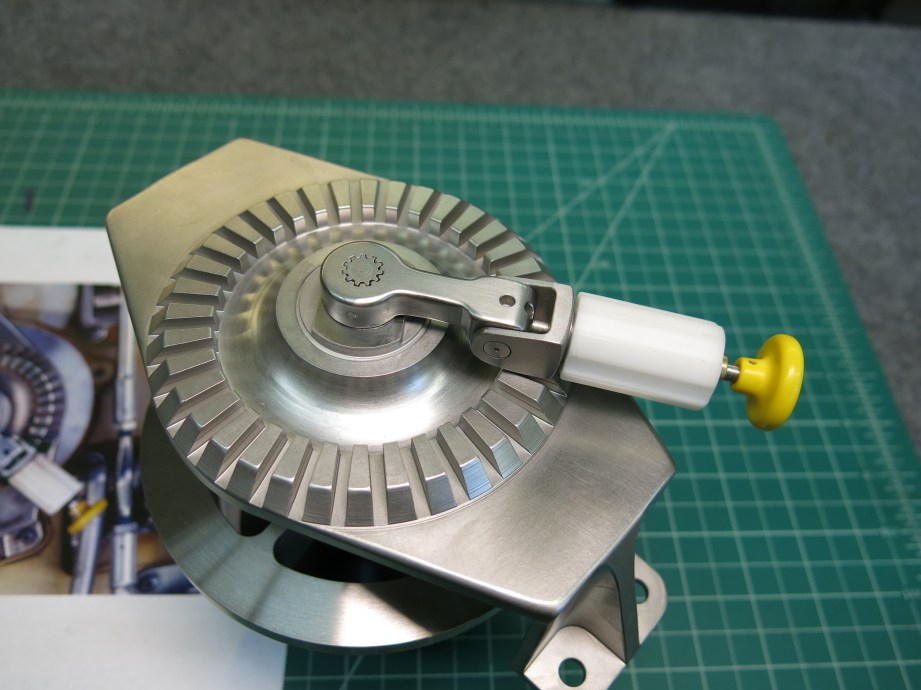

How fortunate that was. As I toured the museum I found a spacecraft related section which included a Gemini program capsule. I don’t remember how long I spent looking at the hatch mechanism but it was a while. I do have a strong memory of being fascinated by the complexity of the mechanism which is exposed on the interior of the hatch. Impressed enough so to snap a single photo of it that plays a strange part in this entire story.

Present day. I was contacted by Adam Savage of MythBusters fame. He was looking for makers to participate in a special project he cooked up. By the way when Adam calls you sit up and pay attention. Of course I’m interested tell me more was my quick answer.

Of all things Adam wanted to recreate the Apollo 11 unified hatch for the 50th anniversary of the moon landing using modern techniques and materials. My first impression was holy cow what are we signing up for. The hi-res picture of the interior of the hatch is certainly intimidating on its complexity and the sheer number of parts to fabricate.

Here is the eerie part. I was offered three assemblies to choose from for my part of the project. Keep in mind there are hundreds of individual parts and assemblies in the unified crew hatch. Of all those parts, and being nearly last in line to be offered a place on the project, it’s down to three parts and me. Out of those three parts that were left there is one assembly that in my opinion is iconic and stands out in stark contrast when you look at the hatch mechanism. It also happens to be what I took a single picture of back in 1987 at a little museum in Kentucky.

I feel a deep seated need to honor the men and women at North American and Grumman that carefully machined the actual parts used for the Apollo 11 hatch. I feel like I’m standing on the shoulders of those folks along with all the mentors and various tradespeople that taught me the craft. I am using many of tools and techniques I have learned from the people I have worked with during my journey in this trade. Many of my team mates that gave a piece of themselves, or a tool that make it possible for me to take on a project like this are no longer with us. In the finest old school traditions I use the tools and skills they gave me to fabricate this assembly and hopefully get that tiny nod of approval from workmates I truly respect and look up to.

There is no question in my mind that this vent assembly will work and function as the North American engineers intended. I could not take on something like this and not have it function as designed using as close to original materials, and techniques as possible. As I work through the different parts of the assembly they all seem to make sense, shapes, sizes, and proportions. Radii are just big enough to facilitate machining, Slots and grooves have the needed tool clearances. Things like that give me confidence I’m going in the right direction.

I chose this part not because it was safe and easy, but because it was my destiny. This part has been flying toward me since the dawn of time. Nothing I could do would prevent it intersecting my life. The quote below sums up my experience pretty nicely.”

We choose to go to the Moon…We choose to go to the Moon in this decade and do the other things, not because they are easy, but because they are hard; because that goal will serve to organize and measure the best of our energies and skills, because that challenge is one that we are willing to accept, one we are unwilling to postpone, and one we intend to win, and the others, too. -JFK

One thought on “Meet the Maker: Tom Lipton”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Show And Tell

Mechanical Dragonfly Automata Kit Build and Review

Time for a model kit build! This steampunk-inspired mechanic…

Wonderful to see my friend Tom featured here. He was an early subscriber to my own small channel and has been most helpful with advice and the occasional bit of tool trading.