The Making of Adam Savage’s Admiral Ackbar Costume

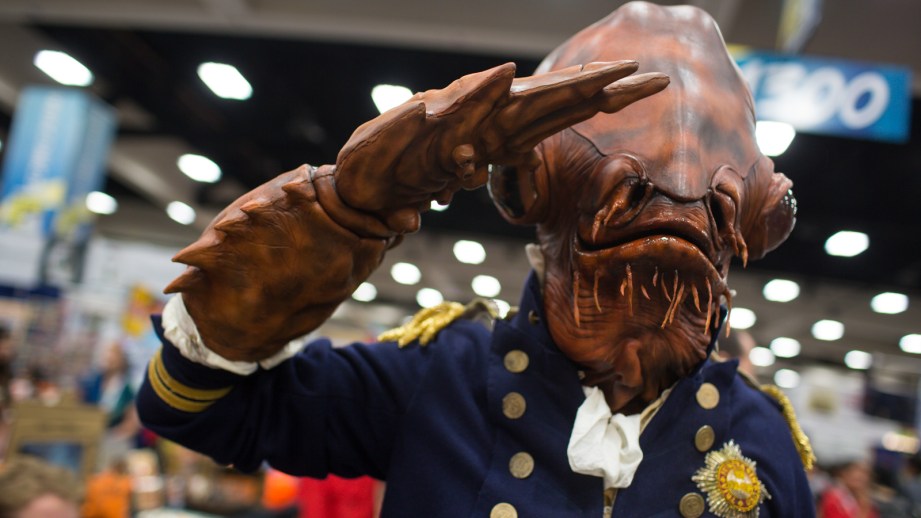

For this year's Comic-Con, Adam walked the show floor as the inimitable Admiral Ackbar. To craft his perfect Ackbar mask, Adam teamed up with makeup master Frank Ippolito to bring the regal Mon Calamarian to life. It wasn't easy, but here's how Adam's Ackbar was made.

I was 11 when Star Wars came out. While the movie as a whole (and the resulting maturation of special effects through the 80’s) shaped me as a person, a nerd, and movie fanatic, I think that not enough attention has been paid to the series’ invention and characterization of non-human characters. Those characters are amazing, to put it mildly. First and foremost, of course is Chewbacca, who may be (alongside 2001’s Moonwatcher, also constructed by the genius Stewart Freeborn) the greatest non-human character in film.

And I’ve gone out as Chewie. First at Dragon*Con 2008 and then several times since then for Halloween and other functions. Chewie is the Bono of non-human characters. People just walk up to you and hug you just because. It’s thrilling to give people the experience of being near a Wookie.

But today I want to talk about Ackbar. Admiral Ackbar to you and me. The leader of the Rebel Alliance for the climactic battle at the center of Return of the Jedi, Ackbar and his fellow Mon Calamarians from the planet Mon Calamari are so awesome they almost cancel out how shite the Ewoks are. Almost.

Like I said, I’ve always loved Ackbar. His huge eyes. His lobster hands. The excellent heavy felt tunic he wears with the super wide collar. It all just works. The combination of elements look just like they should: that Ackbar is a super competent, peace loving fish man from a planet of aliens. It’s clear that you’d like to have a beer with him.

I have collected a few Ackbar masks over the years, but I’ve never been completely happy with them. Don’t get me wrong, there are some lovely fan sculpts out there, but I always strive for the strictest accuracy in my costuming. In my zeal, “Admiral Ackbar” is a search term I regularly entered into eBay’s search field.

About six years ago I hit gold. A foam latex casting, supposedly from original molds appeared in my results.

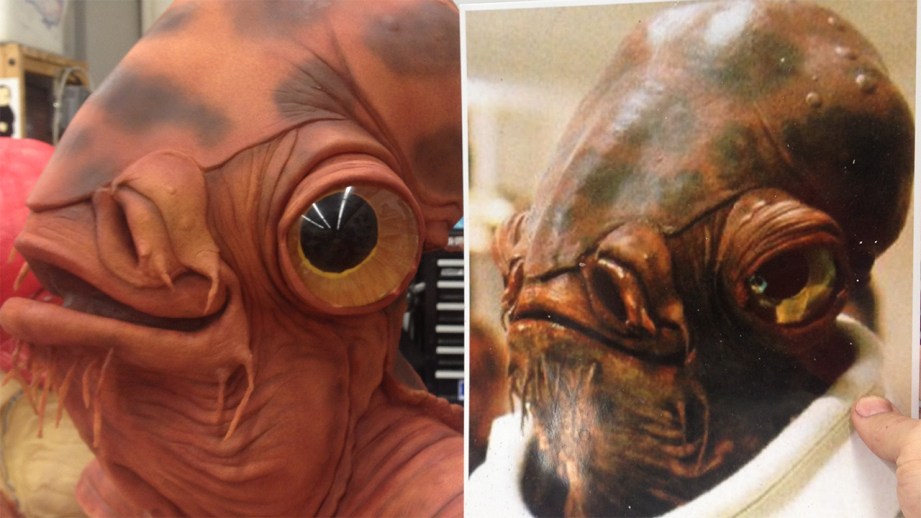

I started breathing heavily. I immediately copied the photo and put it into Photoshop. Then I scoured my Ackbar folder for close ups of the actual mask. Pay dirt: I found a pose of Phil Tippet’s original sculpt in my collection that was in the same position as one of the auction photos. Putting them side by side, and then layering them over each other with a transparency filter, I was able to authenticate that the casting was, in fact, from the original Ackbar molds. The first time, to my knowledge, such a casting had made it out into the world. I snatched it up for… let’s just say it was a good price.

This year I decided to dust off that casting and make a full and perfect Ackbar costume for Comic-Con 2013. Here’s how that costume was brought to life. (Editor’s note: Adam incognito photos here.)

First and foremost I reached out to my friend Frank Ippolito for help. Frank and I had met when he and another friend, Ezekiel Zabrowski (who works for Penn and Teller) directed me in their horror short Night of the Little Dead. In that film I not only acted alongside my friend Penn Jillette, but I also got to have my scalp ripped off.

Frank was also in the first run of the SyFy reality show Face Off, and is actually (drumroll) making a return in Season 5 of Face Off when it airs in August.

Frank was more than willing to help. He would have to do several things to make this costume work. I wanted to be able to manipulate the mouth. I wanted it to be as accurate as possible.

First things first, Frank would have to re-mold the original Ackbar head of mine. Given that it was a soft casting, this isn’t easy. Here’s Frank explaining how he re-molded that piece (with his words in italics).

The Original Plan

FRANK: When I received the mold from Adam, I wasn’t sure what I was getting myself into. We had briefly discussed making it a silicone mask, and that the translucency and movement would be really cool. So I set out to figure out how to make this happen.

First up was to pull a latex/polyfoam copy out of the mold to see what the casting would look like. I used this casting to help map out how it would go together.

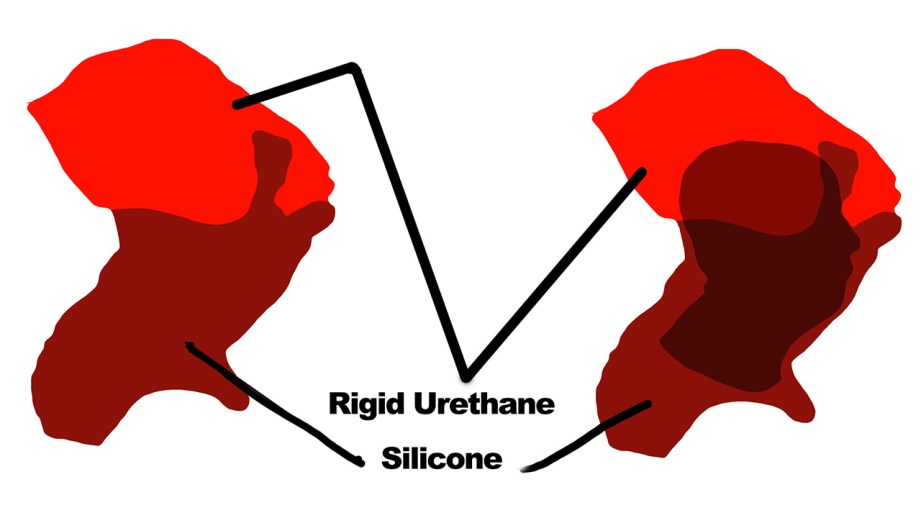

The mold that Adam had had made of his original was a brush-up urethane with a fiberglass jacket. This prevented me from using platinum based silicone (the urethane inhibits platinum from setting up) and the mold wasn’t set up to have a core put in it. So I would have to use a tin-based silicone and brush it into the mold, and try to maintain a consistent thickness.

To save weight (and silicone volume, because silicone is heavy), I thought it might be a good idea to make a hard resin shell on the top of his head, and have that support the weight of the silicone. I cast a fiberglass copy of this part, then started a silicone brush-up into the mold for the rest. Once I got into this process, however I quickly realized I was pushing a boulder up the wrong hill.

This was not going to work the way we thought it was.

The whole thing needed to be started over. I jumped on the phone with Adam and explained my new plan of attack (and how much more it was going to end up costing) and he readily agreed to my new plan.

At that point, I was whisked away to be on Face Off, so for two months I couldn’t work on the Ackbar mask. But I promise you, I lay awake many nights thinking about how I was going to pull it off when I got back. Bonus problem: at that point I would only have three weeks to complete the entire project!

The New Plan

New step number one was to make the best casting out of the existing mold as possible. I used Moldmax Stroke from Smooth-On to do a brush-up, then back filled it with polyfoam. This casing enabled me to fix the errors in Adams original casting and subsequent mold. Upon close examination, I started understanding some key details about Adam’s sculpt and the final mask from Return of the Jedi: I noticed that the nostrils were cut out for the actor to see out of and there were some bumpy sections on the head. There were also little tendrils in the Ackbar head in the film that weren’t in the sculpt. Lastly, and then I needed to fix the seams.

While inspecting the casting, and trying to figure out how I want to divide the mold sections up, I noticed there was a hint of a seam line right up the middle of the head. I’m assuming that the original was molded left/right . As much as I don’t want a seam up the middle of the head (hard to hide, time-consuming to fix), it was clearly the easiest way to tackle this particular mold.

For the mold I decided to use Smooth-On’s Epoxies. The Epoxacote grey surface coat and epoxamite 102 laminating resin would work out great for this. I used a little Freeform Air (also from Smooth-On) to fill in some sections between the surface coat and the glass layers (5 layers of 10oz cloth) When the mold sections are done, I trimmed it and glassed in some t-nuts. I like to do this on most of my molds so that you don’t need to fumble around with a nut on the other side of the flange, just zip in the bolt, and be done. This allows the fiberglass mold to be quickly and easily assembled and disassembled.

While this was all going on, I brought in a couple friends to work on the hand sculptures. Eddie Holecko blocked the sculpture out, I Refined them, then Alana Schiro and Nora Stahl worked on texturing and smoothing. This freed me up to also sculpt other details in between the gajillion other steps I still had to do. We did all of the sculptures with Monster Clay (from Monster Makers in Cleveland).

ADAM: My purchased casting had no eye stalks or eyes, even. Frank would have to re-make the eye stalks from scratch. I didn’t need them to move or blink like they did in the film (I’ll add that later, can you say Arduino?) so they’d just end up being static additions. But what about those deep clear eyes of Ackbar? How to do those?

The thing is, clear casting materials are really difficult to work with. Fortunately I came up with an idea a few years ago and I suggested it to frank: What about using a pair of those book magnifiers? Like the one that came with my Oxford English Dictionary that’s in the Cave.

For reference, I had pictures of a pair of Ackbar eyes that sold at auction a few years ago. They had been painted by Phil Tippett and they gave fantastic details about the paint job. As Ackbar’s eyes are a crucial part of the costume, we had to get this right. And Frank did a superb job.

The Eyes

FRANK: To sculpt the eye stalks correctly, I made some quick castings out of adams original mold with ‘Free Form Air’ of each of the eye sockets. This will give me correct shapes to get the forms of the sculpture right. I use some monster clay around a urethane casing of the eye form. My pal Miranda Jory finished off the texture on the eye stalk sculptures while I was jumping back and forth between other steps for Ackbar.

To mold the stalks I just boxed them up individually and poured in a 40 durometer platinum silicone from Smooth-On. Having a flexible mold saved me from making a two-part epoxy mold and having to seam the eye stalks. The rubber helps let the eye from flex in and out since its a tight fit in the thin stalk.

For the eyes, Adam had suggested a 3-inch magnifying dome, so I ordered a couple of these. Adam also sent me a picture of an Ackbar eye that was up for auction at some point, (From Phil Tippett’s personal collection) which gave me a great image of what the eye’s paint job was like. I took this into Photoshop and stretched the off-camber photograph into a clean and perfect circle.

Then on a new layer I painted over the existing reference to give myself a nice clean image of the eye. After a couple tries, I got the size right for magnification and printed it out, and epoxied it onto the back side of the dome.

The Head

FRANK: Back to the head mold. With the two halves of the fiberglass mold done, I need to make a core. The core is also made from fiberglass and allows us to inject a special foam latex into the mold that comes out the perfect thickness and also makes sure that the actor’s head fits in the mask.

Because I had torn off Adam’s scalp during Night of the Little Dead, I had a master mold of Adam’s head that had been used during that production. An accurate casting of his head would allow me to perfectly fit the Ackbar to Adam without any guesswork.

I took my casting of Adam’s head and positioned it in the mold approximately where it wanted to be sitting, and lay in water clay to represent the desired thickness of the final casting. Then Chris Alexander and I glassed up the two halves of the core and then I glassed them together once the mold was bolted closed. When this is all set up, all I had to do was clean it out and send it off for foam latex.

In this process, the outer fiberglass mold was bolted together, and then the core bolted to the outer mold. Foam latex, about the consistency of a makeup sponge, is injected into the cavity between the inner and outer mold.

I split the foam runs up on this project between two friends that have their own shops that only run foam and do castings. Roland Blancaflor and Mark Viniello. Once their foam castings were done, they needed to be seamed and patched. Between scissors and burning with a hot tool (like soldering iron) the seam is removed while small batches of foam latex are put on the seam to fill the tiny gap. This was done by Tim Leach. It’s hard work to get right, but crucial to remove evidence of the mask’s manufacturing process.

The Hands

Just like with the head, the hands had some last-minute changes. Originally, we were just going to run slush latex copies, but because we opted to make more long term epoxy molds on the hand sculptures, this is a bit counter productive when it comes to casting latex.

The normal mold material for latex is plaster. As plaster is porous, it holds on to the latex so that the resulting casting is exactly the shape of the original mold. Epoxy isn’t porous, and as the latex dried in the epoxy mold, it shrunk. I also had to rotate in the latex in layers, otherwise it will never dry.

After the first layer, I noticed it pulling away from the surface as it dried, so…lets just say there was another late night call to Adam to approve another deviation in plans, and I jumped into making another set of fiberglass cores for the hands, the same way I did the head. Also like the head, these would have foam latex injected into them.

Assembly and Finishing

The eye stalks that I sculpted (and molded and cast in foam latex) were glued in place with barge cement. I also needed to make a core to fit inside the foam casting to hold the shape of Ackbar’s quite large head. Without this he might look great from the front, but a bit like a deflated balloon from the side. Unacceptable.

I made a quick plaster bandage mold on the head’s fiberglass core and then lay in a thin layer of fiberglass inside that. I added little bit of soft polyfoam to the inside so that it sits on the head correctly and is (hopefully) comfortable. Once it was trimmed up, I fitted it into the head mask and move onto the last details.

Ackbar has a bunch (17 that I can count) of little tendrils on his chin and around his mouth. From the reference I had, I figured I could make these by rolling a little cotton in latex, then gluing them on the foam casting. Bingo. It worked like a charm.

Painting

Time for paint! The paint scheme for Ackbar is pretty simple, I used just four colors to get it done. A salmon-ish color, purple-ish red dark brown, yellow and burnt umber.

To paint a foam latex mask, I prefer taking rubber cement and thinning it with naphtha, then tinting it with oil paints. This can be airbrushed or hand painted on. It doesn’t clog the details, and sticks perfectly to the flexible foam mask material without too much wear and tear as it moves.

My buddy Doug Stewart (who is a great painter) popped over for a couple hours to jump on helping me with the paint. Final touches were to spray some v-gloss sealer and put a little silicone on the mouth and nose to keep the wet look. Done and done.

In hindsight, I would use a vacuform of the core inside of the foam latex casting, and use mattress or reticulated foam to cut down on some weight. I also think the eye domes are too dome-y. The pictures seems to show his eyes being a little flatter. Maybe a machined and polished form would be more accurate. Also adding a simple spring mechanism that can be controlled via cable down to inside the hand would make mouth movement really cool. Eye blinks would be tough, unless the new eye form was designed to accommodate. Even a little voice modulator or sound board thing would be cool to have in the head.

People that helped with this Project:

- Nora Stahl

- Eddie Holecko

- Alana Schiro

- Miranda Jory

- Chris Alexander

- Doug Stewart

- Mark Viniello

- Roland Blancaflor

- Tim leach

Build photos courtesy Frank Ippolito. Find more of Frank’s work at Frankippolito.com or on Twitter @frankippolito

See more photos of Adam as Admiral Ackbar, getting ready and walking through Comic-Con, here.

17 thoughts on “The Making of Adam Savage’s Admiral Ackbar Costume”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Show And Tell

Mechanical Dragonfly Automata Kit Build and Review

Time for a model kit build! This steampunk-inspired mechanic…

Its a trap!

Very impressive!

Stroke of genius, mixing the mask with the Master and Commander garb.

Absolutely incredible. Great build.

Amazing mask, great to read how it was made.

I love that Adam walks around and people try to spot him, but wouldn’t it be sorta easy considering he always has better than movie quality costumes made for him? I’ve never been to Comic-Con, and I know fan made costumes are out of this world awesome, but don’t his have just that little bit extra that would make it a bit easier to spot him?

This looks amazing.

I think it’s pretty easy to spot Adam… Just go for the highest quality ones.

Awesome costume, Adam! 🙂

And thanks for the story on how it was made..

Well… on the one hand there’s plenty of professional cosplayers, there’s people in costume to promote stuff, and there’s entire communities of people who are just as into making costumes as Adam. In fact there tend to be several professional make-up and costume studios that go the Comic-con as well. (Also, some of the amateur costume and make-up people have to do things better because they can’t rely on lighting or post-production)

On the other hand, some of Adam’s stuff is deceptively simple. By example, no-face wasn’t a super ambitious project but worked really really well.

Dammit, you’re right. I forgot all about the pros that go to these events and we even have one writing a series of articles about how he makes props. I can’t believe I didn’t think about those guys and girls!

LMFAO good one

As great as the mask work is, Adam & his minions didn’t skimp on the rest of it. He’s wearing a copy of the coat that got Admiral Nelson killed at Trafalgar, plus correct breeches, boots, and shirt. Not only is it a trap, but they’ve got sharpshooters in the tops! http://www.portcities.org.uk/london/server/show/conMediaFile.1752/Nelsons-Trafalgar-Coat.html

+ 10 Points for the Strung Out sticker in the final image.

Fantastic write up.

+1 fantastic write-up, on an impressive project.

Nitpick: someone clearly doesn’t know what inimitable means.

I saw a picture of this outfit on a nerd page on Facebook for Comic Con and knew it was Adam instantly. So cool. Would be pretty awesome to have a Ackbar mask on my shelf.

Polyurethane and silicone are amazing. You can see also Ceste l company products about these products. http://www.cestelkimya.com/concrete-mold-casting-rubber/?lang=en

Actually there are few companies in mold making resin. One the best company in urethane rubber resin is Cestel. Cestel urethane rubber series are famous for their abrasion resistance and high tear strength. Mold Cast30 is the softest of our product and offers the most flexibility and is used for models with deep undercuts. It has superior abrasion resistance and tear strength and are ideal for casting concrete. These rubbers are used for casting of concrete. You can check http://www.cestelkimya.com/concrete-mold-casting-rubber/?lang=en for more information