Bits to Atoms: World Maker Faire 2014 Recap

I've been to every NYC Maker Faire and it keeps getting bigger. Since Will and Norm were unable to make it this year, I wanted to share with you some of the projects and cool stuff I saw.

Hey everyone, Sean here with a World Maker Faire New York recap! I’ve been to every NYC Maker Faire and it keeps getting bigger. I’ve had a booth the last two years but was too busy to get one together this time. The upside was I actually got to see the convention and all the new 3D printers and accessories that were either just announced or being shown in person for the first time. Since Will and Norm were unable to make it this year, I wanted to share with you some of the projects and cool stuff I saw.

Within seconds of setting foot in the 3D Printing Village (one of World Maker Faire’s biggest draws) I ran into Anthony Campusano, a fellow maker who I’ve met numerous times and builder of an amazing Lament Configuration box from Hellraiser.

The fellow with him enthusiastically exclaimed, “I follow you on Twitter!” and it turns out to be Andreas Ekberg, who made the Tested Cruiser skateboard! I didn’t realize it until later but Andreas is also responsible for the Classic LEGO Spaceman print that has been on my to-buy list. I had a great time hanging out with my fellow makers. Now let’s take a look at some of the good stuff I saw.

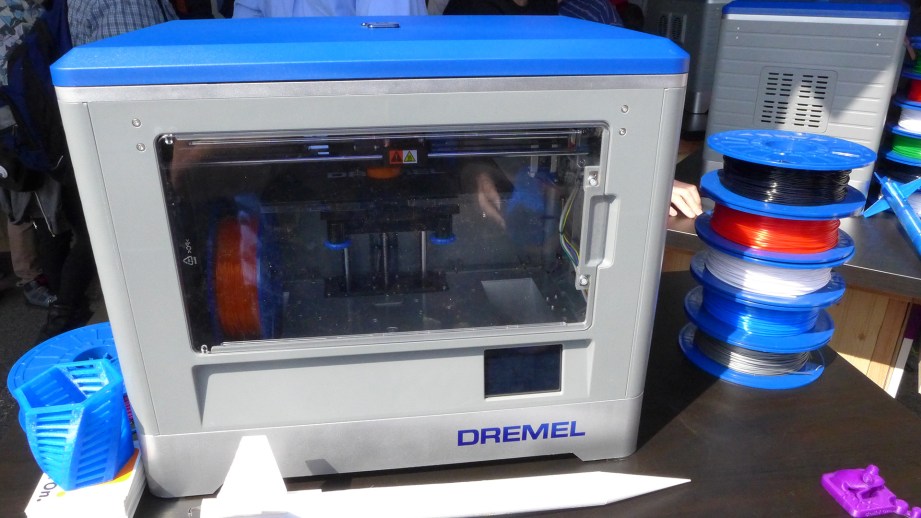

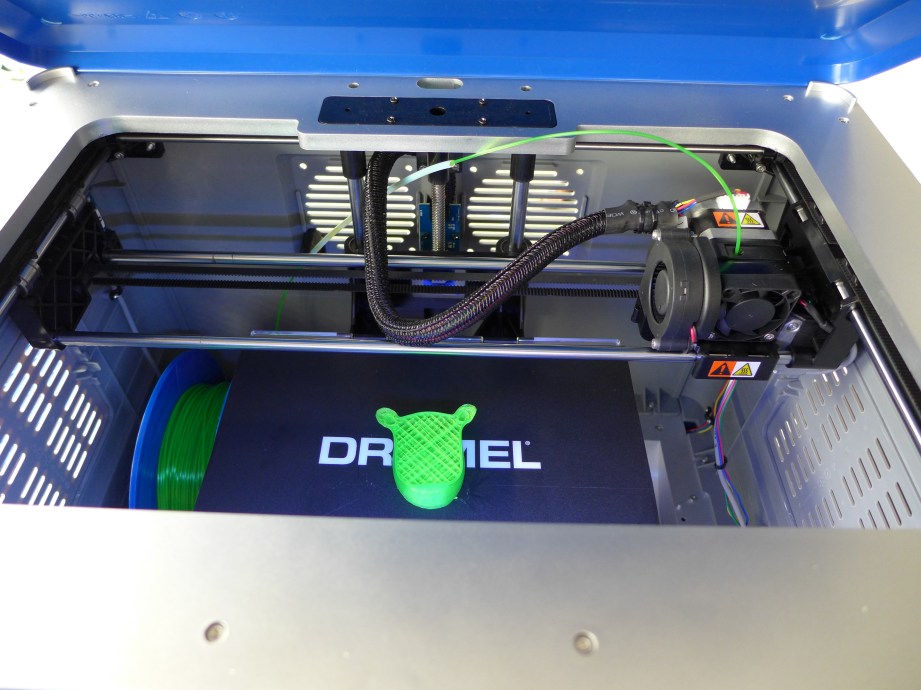

Dremel’s 3D Printer

Dremel recently announced their 3D printer which I think is going to be a pretty big deal when it’s released in November. Design-wise, it’s similar to the MakerBot Replicator 2 which is good news since that printer has since been discontinued. Dremel’s printer is designed for printing PLA with a non-heated print bed and active cooling fan. It’s completely enclosed for safety with a magnetic front door and a top the lifts right off–if I owned the machine I would remove both. The custom-sized .8 Kg spools sit inside the machine, which mean other manufacturers spools won’t work but you could easily mount it outside the machine.

The printer has a 3-point manual leveling system with large, easy to turn knobs and a removable polycarbonate bed to make print removal easy. Dremel is using BuildTak (see below) on the print bed for improved print adhesion. They are using a spring-loaded extruder feed mechanism which has become the preferred setup for most of us. I like that they chose a pretty standard setup that can be disassembled. Since extruder clogs are going to happen no matter what, I asked them if they would cover extruder disassembly in the manual. They said ‘no’ but they would walk customers through it via a support line. Print quality looked good but they weren’t demonstrating the software, so I didn’t get into that.

Finally, Dremel’s printer uses USB or SD card for model upload and has a decent size touchscreen interface for control. I predict this will be a hot machine as it’s from a trusted brand with wide reach and has a nice price point at $999. Spools run $30 for .8 Kg which put them at about the average price-point for PLA filament. Since this is Dremel, I asked if this meant we would be seeing a desktop CNC machine soon and they just grinned.

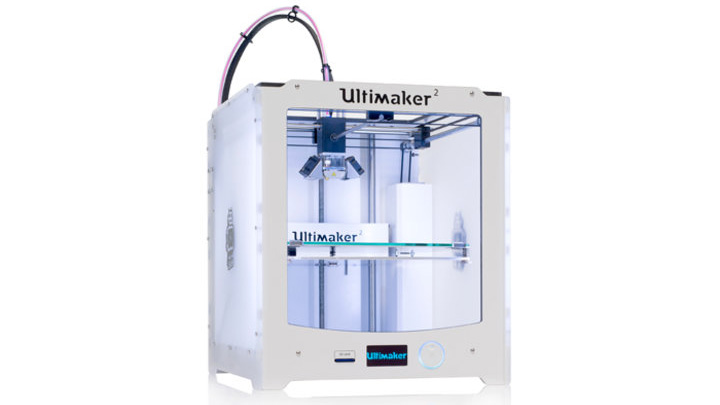

Ultimaker 2

Although I have never owned one, I have always liked Netherlands-based Ultimaker machines and the Ultimaker 2 is really pretty. Ultimaker has always produced really nice prints and unlike MakerBot they still embrace their roots and offer the original Ultimaker as a kit. The 2 model comes fully assembled and can print ABS or PLA using 3mm filament. The 2 has a heated glass print bed for ABS printing, although the unit is not fully enclosed so I’m curious as to how large ABS prints will turn out. It still uses a bowden extruder, which means the filament is pushed through the feed tube by a mechanism on the back of the machine. This allows them to keep the actual extruder head very small and light which causes less momentum problems while printing at high speed. The Ultimaker 2 runs around $2500 and is a great looking machine from and established 3D printing company.

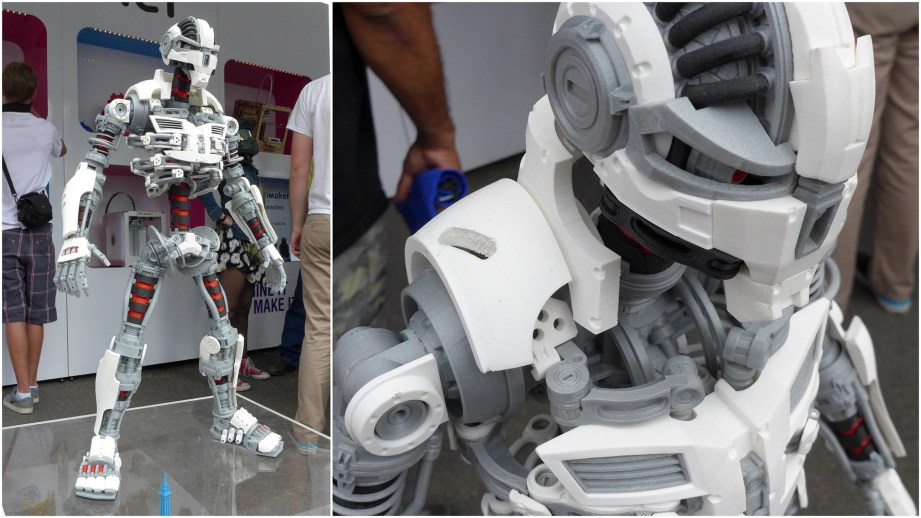

As a bonus, Ultimaker had Valcrow’s work on display and I was extremely disappointed to find out he had been hanging out at the booth and I missed him! As I mentioned before, you can download and print his lightsaber and Ducati motorcycle models. They also had something I had not seen before, Aaron Thomas’ impressive Ronin mecha that was completely printed on an Ultimaker. This guy was at least 18″ tall and had an incredible amount of parts and detail.

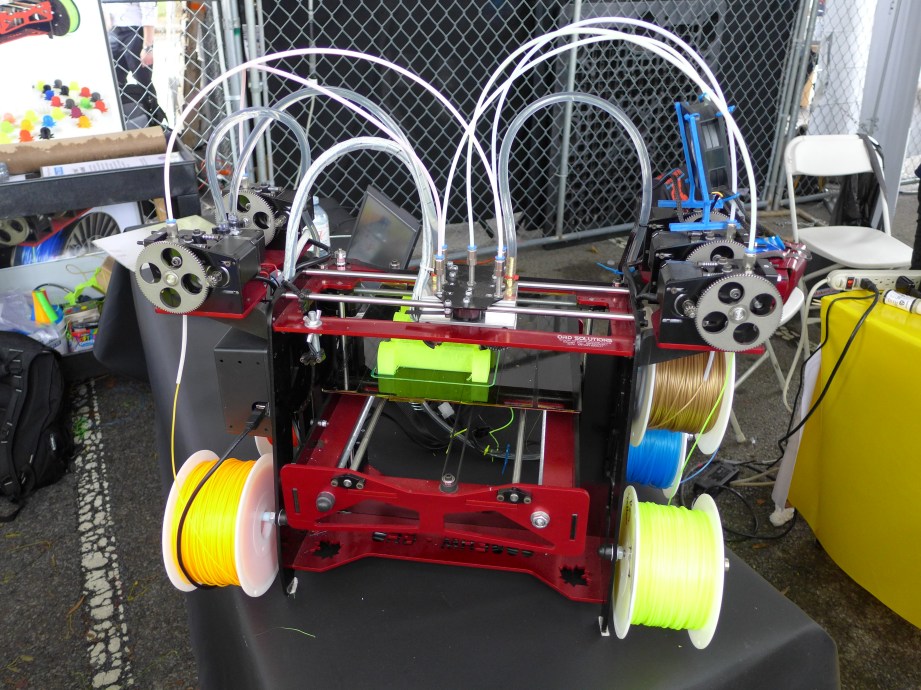

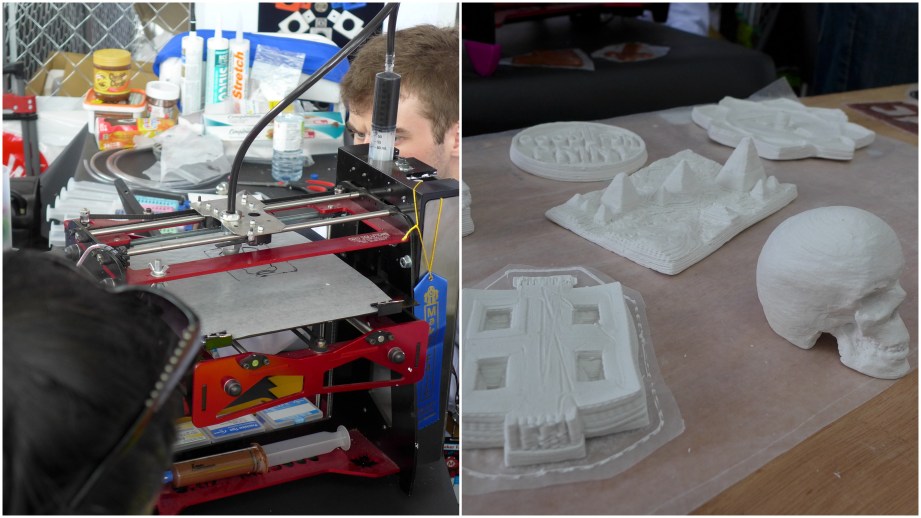

RoVa3D Printer

ORD Solutions from Canada had probably the craziest 3D printer that I saw at the Faire. They already had a successful Kickstarter for the RoVa3D 5-head printer. Yes, that’s right, five heads with liquid-cooling to prevent jams–this thing was impressive to look at. Construction quality looked top-notch, although you don’t want any small children around this thing with open print bed and stainless steel gears. It has a heated printbed, but once again, a fully open-air design can make printing ABS challenging. Print quality was very good and the five-color examples didn’t seem to have too much bleed/boogers between the colors. At $2500, the price is hard to beat if it delivers on quality and tech support.

Even cooler was their current Kickstarter for a paste machine which is retrofitted to print with anything from plaster to peanut butter! In a field overrun with Kickstarter machines ORD looks to be making unique machines with some quality construction.

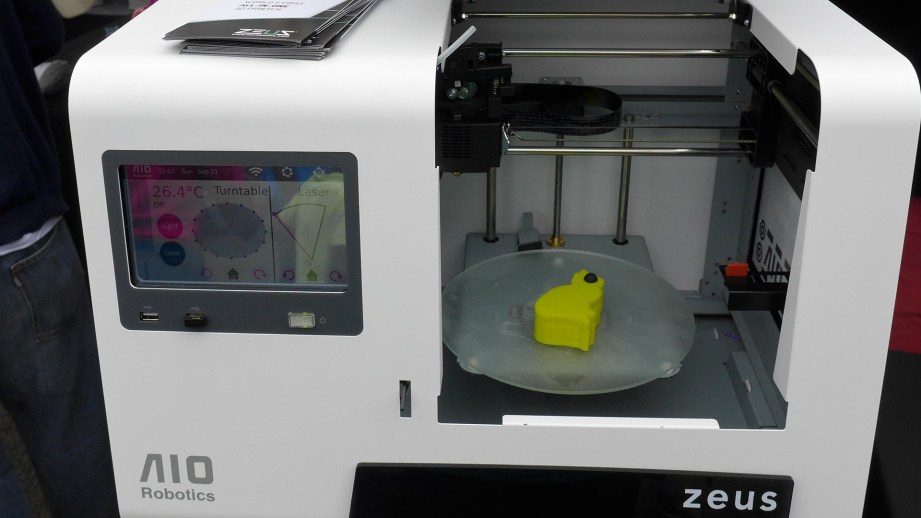

Zeus

I unfortunately did not get to speak with the rep for Zeus printer which was successfully funded on Kickstarter, but it looks like a doozy. For $2500, It offers up scanning, slicing, printing and ‘faxing’ (that’s right) all in one unit. Construction didn’t look bad, print quality looked on par with other printers but I don’t know what objects I was seeing were scanned by the Zeus. I’m wary of this much packed into one unit for this price-point and look forward to hearing some real reviews.

BuildTak

BuildTak is a thin, textured plastic (reminds me of thin kitchen cutting mats) with adhesive on the back that you stick to your print bed instead of using painter’s tape, kapton or glue sticks. They have custom sizes for most popular printers or you can cut it yourself. Both Dremel (see above) and Afinia are using it for their printbeds and for only $10 I decided to give it a try and will report back later. The finish samples they had on hand weren’t smooth like when using kapton, but they were also nicer than painter’s tape and it seems to work with just about any filament.

It’s heavy enough that it seems tough to damage and cheap enough to replace if you do. You can not use acetone to clean it like I do for kapton, but alcohol is ok. Since it behaves differently than other surfaces, you probably need to set the nozzle to printbed gap differently than normal.

Printed Solid

I was not familiar with Printed Solid before this Maker Faire, but they are offering up unique printer supplies and services. They are carrying Netherlands-based colorFabb filaments which have gorgeous PLA colors as well as some really exotic stuff such as wood and metal impregnated filaments. They have recently introduced XT filament, a copolyester that has low odor, is FDA compliant, prints like PLA but is tough like ABS–this stuff looks really promising. Printed Solid hooked me up with some woodFill and I bought some bronzeFill and will report back later with results. Printed Solid also offers services such as design and metal casting and silicon molding from 3D prints.

3D Kitbash

I spoke with Quincy and Natalie of 3D Kitbash who are offering up digital downloads for printing on your own machine. They have the Boneheads series of skulls including mounting plaques, printer test kits for calibrating your printer and Quin, their fully articulated doll. The work on Quin was really well done and fully printable on a FFF machine. She has various add-ons and options available for download and they are working on themes for her as well. I like that they are offering downloads as an STL which gives you a lot more flexibility in printing versus sites that are offering models only formatted for a specific size and printer.

Modio

Modio’s stuff was very neat and where I can see toy manufacturers going. They make an iPad app that gives you a palette of modular pieces to building your own action figures and then print them at home. I really like the aesthetics of their parts which just snap together to make some cool figures. They really need to offer more than just an iPad app and get this on Android as well as a web app.

UPDATE: Modio contacted me – they just released an iPhone app and are working on other platforms as well.

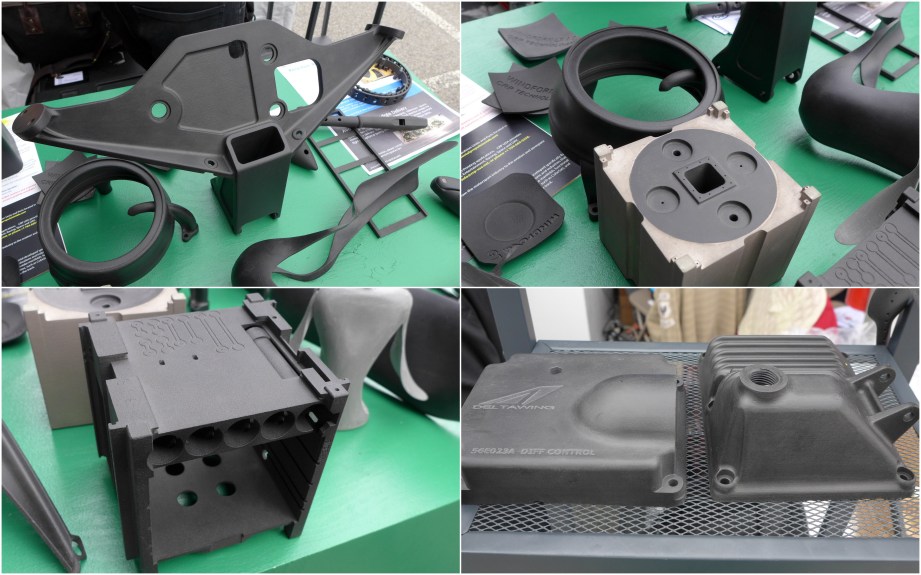

CRP

CRP had some of the coolest 3D stuff I have ever seen. While their services are out of reach for us mere mortals, they came to Maker Faire to share what they do – making 3D printed carbon fiber parts for the likes of Formula 1 and NASCAR. They use modified 3D Systems SLS (Selective Laser Sintering) machines to print extremely light and strong parts for high-end applications. I was able to take one of their 3D printed carbon fiber parts that was dish-shape and pop it inside out and it popped right back into place with no problem – amazing stuff.

That about wraps it up for my experience at this year’s World Maker Faire. It was a great time as always and I even got recognized as Adam’s Inventern! Maybe next year I’ll see you guys there.

12 thoughts on “Bits to Atoms: World Maker Faire 2014 Recap”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Show And Tell

Mechanical Dragonfly Automata Kit Build and Review

Time for a model kit build! This steampunk-inspired mechanic…

It’s good to know that you didn’t have a booth this year because I went all over the faire looking for it. Saw so much amazing stuff. The Smithsonian exhibit exhibet, the huge 3d printer in the science museum, the guy making a scale model of Luna Park, the “enhanced” pinball machine. My feet are still sore.

Great wrap-up, Sean! Let us know how the BuildTak performs, as I’m growing weary of the hairspray on glass bed approach I’ve been using on my Prusa 8″ with ABS (gets all over my Y-bed tracks and cables).

Sorry I missed you! After I ran into Andreas it occurred to me that I should have made an announcement and us Tested folk could have met up. I got so tied up outside that I never made in to see the other stuff. 🙁

I put it on last night and first tests look very promising. They told me to make the nozzle-bed gap larger than normal because it doesn’t need to ‘smoosh’ the first layer like with tape. I slightly increased the gap and printed some ABS – could barely get it off the bed! So if anything, it may stick too well if you’re not careful. I do miss the smooth glossy finish that kapton gives you but it occurs to me that if you really needed that for a print you could just put some on top of the BuildTak. Will update further after some more prints.

Thanks for the heads up on the buildtak, just ordered one can’t wait to test as I’m tired of using tape and 3M spray mount on my simple metal

It looks like Dremel printer is using the exact same injection molded parts for the gantry as the Replicator 1 & 2/2X use.

Right? It’s totally a Rep 2 which is nice since it’s discontinued. Looks like they upgraded to linear bearings.

Here’s some more pics from Solidsmack:

http://www.solidsmack.com/cad-design-news/world-maker-faire-nyc-2014-visual-journal/

I will get mine up soon, but I’m sort tied up with another project.

I read an article that said Dremel partnered with FlashForge, who apparently makes Replicator clones. I don’t know if there are any legality issues with how closely FlashForge is copying Makerbot’s machines, but as an American, I’m a little disappointed that Dremel is bringing business to a non-US company, which makes at least some of its money selling cheaper knock-offs of an American company’s products. I’m not saying I think everything has to be American — I’m just saying Dremel started as an American company, and still has its headquarters in America, so it would’ve been nice to show a little home team support in the nascent 3d printer industry.

Great writeup 🙂

Sean, It was great to meet you and and a lot of fun talking at the Faire.Thanks so much for including 3DKitbash.com. – Great Write-Up! I was stuck in the booth most of the show, so this has helped a lot with understanding the other great items that were there.

It looked to me as if Dremel’s printer was it’s market entry printer, done on the quick with as few resources as they could get away with. If they worked with some body for the guts, it wouldn’t surprise me, but I think that a lot of printers are going to look like Replicator 2s simply because most of the Replicator2 was open source. The next round is going to be the interesting one as everybody works to come up with proprietary stuff that differentiates them from every body else. The joker in this deck is who wasn’t there. Where is HP? I’ve heard rumors about them working on a 3D printer, but I haven’t seen them show up at a show yet. If they are keeping back, they’ve got something that’s going to be a knockout. Remember through their plotter and inkjet printers they’ve been playing with the key technologies involved for decades. That experience is going to make an impact when it hits.