How To Build the 3D-Printed Cutaway Lightsaber Kit

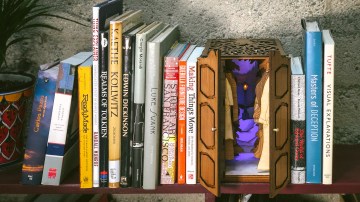

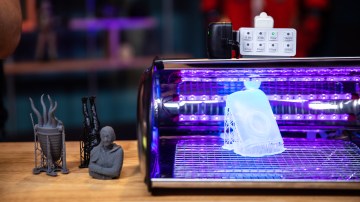

Sean walks us through the assembly of his 3D-printed cutaway Sith lightsaber, showing us how to put it all together from parts you can print on your own printers (files here)! Along the way, we learn about the design of the individual pieces and get some tips for printing on the Formlabs Form 2 SLA printer.

Shot and edited by Adam Isaak

Music by Jinglepunks

15 thoughts on “How To Build the 3D-Printed Cutaway Lightsaber Kit”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

what’s up with your playback lately, I keep getting dead videos.

Same

Video problems resolved. Great presentation Sean.

Awesome project Sean and the saber is looking good. Can I ask you what make and model your wrist watch is? don’t want to be rude, I just think its cool

St Moritz Storm

so well done – makes me want to get a printer

When you mentioned you forgot to mention your wife glued al the tiny grip parts in place, I thought.. “oh oh”… Then I watched the video and it gets WORSE! you say “I glued them in place” MULTIPLE TIMES!

I guess you’re sleeping in the dog house for a few days 😛

Fantastic build. I love the attention to detail and especially the cutaway. I can’t imagine a better way to highlight the Formlabs printer and its full capabilities. Great job Shawn. It certainly has me watching Formlabs for the right opportunity to purchase.

I’m looking forward to the build details. Maybe you can include some of these questions below?

How many cartridges you used in the prototyping and design of this build?

Maybe separately how many to print a completed design so we can understand the ratio of materials used in design vs final output.

Do you need separate resin tanks and build platforms for each resin type? Presuming those are also consumable over time,

I ask mostly because of the high cost of the proprietary resins. I’m surprised they don’t partner with someone like Smooth-on to integrate their high volume materials production with their machine. Clearly there seems high potential and overlap in the professional and hobby prop design and building community. I also have concern about resin availability over time. The machine is quite an investment, and getting locked into proprietary resins adds risk, there are less guarantee’s of long term support.

Looking forward to see what’s next.

I can answer a few of your questions, just remember this is knowledge gleamed from reviews and technical videos not first-hand experience.

Most SLI printers use liquid resin you pour into the tray reservoir, those trays are reusable and you need to clean them as well as the build platform before changing resin. The resin sits open to the air in that tray, the build platform is suspended above it and pulls the object up out of it.

The resin is not metered out in any way with form labs printers, the printer doesn’t really know how much resin it has in it, it just prints the object and whatever is left is excess, if you had too little it would keep trying to print without resin to print with.

The tray and build platform does take wear but presumably you would never need to replace them if you take good care of them.

I will be touching on some of that stuff in upcoming article – so stay tuned.

Also, the Form 2 does monitor the tank and auto-fills and/or pauses as needed. Generally you want a dedicated tray per type of resin and they are rated for about 2 cartridges (2 liters) before they need to be replaced. Eventually the laser clouds the silicon bottom and prints suffer. In practice I have gotten longer life out of tanks but it depends on how big the objects you are printing are which dictates how much of the tank sees wear and tear.

Great work, you mention adding the supports manually with a tablet? Can you elaborate on this a little bit. What software did you run on the tablet?

keep up the great work

Thanks, that’s useful and makes sense, just more wear than I had expected. That does make it a bit harder to justify in some conditions. The fidelity is very nice, but guessing cost per piece, it would be more cost effective to make a mold and cast duplicates.

With that in mind, Maybe in a future article there’s an opportunity to test how well the materials work both as a mold and in as a model for casting. I wonder if you could cast silicone or polyurethane foams in a mold printed on the finished formlabs materials. Alternatively I’d also be interested in knowing if the various print materials are platinum silicone compatible, or would you need to choose another material to make a mold of a printed part. Maybe that’s a future opportunity to coordinate with Frank and Smooth-On on something interesting.

Thanks again.

Will cover this in upcoming article.

Have Adam build one too. Painting and weathering also.

There are a lot of ways to make a light saber, one is easier than other… or i would say “faster”, but I would like to see something like wooden light saber’s handle or some detail that only could be done by hand!