Meet the Carbon M1 Super Fast 3D Printer

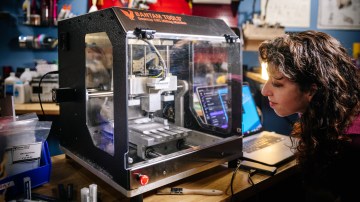

Watch this complex object get 3D printed in less than 15 minutes. Sean and Norm visit Carbon, the makers of the M1 3D printer, to get a demo of this new super fast 3D printing technology working in real-time. We chat with Carbon’s VP of Product, Kirk Phelps, to learn how the CLIP 3D printing tech works, and why it’s more than just about really fast prints.

Shot and edited by Joey Fameli

Music by Jinglepunks

11 thoughts on “Meet the Carbon M1 Super Fast 3D Printer”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

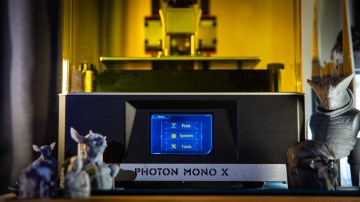

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

That is super cool. The flexible prints were pretty amazing.

wonderful sales pitch

Get a feeling light and oxygen is important to this process…

If anyone is curious, the two patents they have are the following:

http://www.google.com/patents/WO2014126837A2 – Interesting one

http://www.google.com/patents/WO2014126834A3

All pulled from: https://en.wikipedia.org/wiki/Continuous_Liquid_Interface_Production

I found the figures from the Science paper last year pretty interesting too.

http://science.sciencemag.org/content/347/6228/1349.full

I can only imagine the cost savings of having a few of these printers around the world to make parts for things as opposed to building warehouses. I bet they are expensive printers but on the other hand cheaper than a million dollar warehouse. This will change everything in the equipment support business.

That’s a bummer we probably won’t see this technology until the patents expire.

US$40,000 per year, minimum 3 year term, plus accessories and consumables.

https://s3.amazonaws.com/flabs-carbon/downloads/pricing/Carbon_Pricing_April2016_A.pdf

I think we’ll be waiting a while for the prosumer version.

Depending on the stuff you’re making, the ROI could be enormous. Companies like Shapeways cost a relative fortune to have things printed. The cost of that CE resin, though…

Excellent interview. The deeper level of tech and science in these discussion is very exciting. Keep up the great work.

Scurr This is an idea I had a couple years ago when the 3D printers just started getting popular. I work in autobody and we’re constantly ordering parts. Alot of them plastic. Clips, brackets, shrouds, etc. Instead of having a clip bin that has to be kept stocked or having a brand new part on back order because its the current model year there could be a 3d printer like this one in our shop with a licensing fee for each print. I could potentially be much faster and more cost effective for the consumer and the manufacturer.