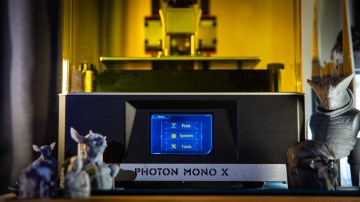

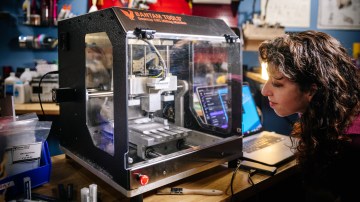

3D Printing Molds for Silicone Masks!

We’re in Frank’s new shop to check out his testing of the 3D Platform printer! This commercial-grade printer alows him to make massive 3D prints that are beyond what’s possible with home printers, including swords, armor, and even large molds for casting. One experiment Frank has been working on is printing molds for hyperrealistic silicone masks!

7 thoughts on “3D Printing Molds for Silicone Masks!”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

How feasible would it be to use 3D printed molds for vacuum forming?

I helped a company that does vacuum formed parts for packaging transition from hand made molds to 3D printed molds and they couldn’t be happier. They were able to drastically reduce their prototyping time, lower costs and deliver to customers quicker.

Have a watch of Bill Doran of Punished Props answering questions about prop and costume making. https://www.youtube.com/watch?v=c7Fm_0_pFmE the question about Vacuum forming is at 18:00 minutes some useful tips there

I’ve been playing around with that… The heat wreaks havoc on them. PETG holds up OK for a couple of pulls. PLA not so much. Coating with XTC / epoxy / fiberglass helps a bit.

Best I’ve done so far is vac over the print, then use the plastic as the mold for a Smooth-on TASK-8 resin casting. The TASK-8 takes the heat like a champ. Using that 1st pull as the mold isn’t as detailed as if you used silicone, but depending on the part you may find that the price/speed of a styrene mold is worth the loss in details.

ABS has a higher heat threshold. What about that material?

Franck always over the top!

Absolutely ABS will work for more than a few pulls. I work with Formech, a vac-forming manufacturer. We have ABS demo molds that I have been utilizing for years. I am just sure to let the mold cool down a bit before the next cycle.