Maker Profile: Michal Miszta’s Custom Engagement Ring Boxes

Michal Miszta makes the most amazing custom engagement ring boxes based on Disney movies. Here's how he does it.

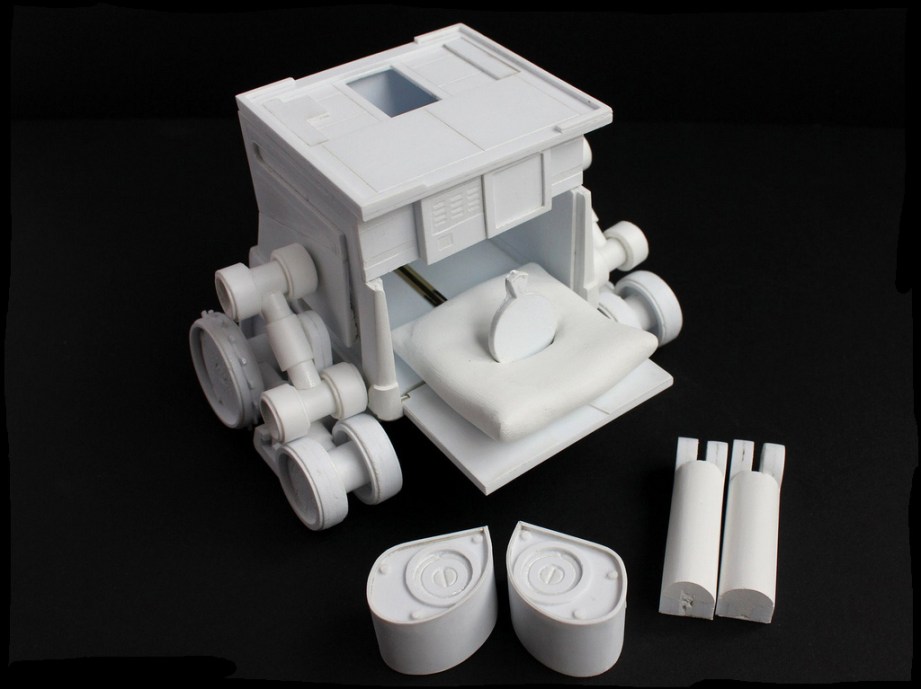

Carl Fredricksen’s floating house from Up. The toy chest Woody and Buzz Lightyear live in. Tinkerbell’s Lantern home. Wall-E. Artist Michal Miszta has used these iconic objects from Disney movies to create memorable custom engagement ring boxes for friends and clients. The Dublin-based sculptor works as an architect by day, but his hobby is crafting amazing custom sculptures and miniature buildings using blank vinyl toys, polymer clay, and epoxy putty. Some of his creations bare absolutely no resemblance to the Munny figure underneath–this Baby Dragon for example won the Best Sculpting award at a KidRobot competition.

I chatted with Michal about his creations and how he approaches the task of creating a custom figure and engagement ring box.

What is your background in model making and custom toy design? Where did you learn your skills?

I am self taught model maker, and have never had the occasion to be employed as one in any workshop. I work as an architect in Ireland. I planned to open my own architectural model making practice but this decision came right before great crash on the housing market so it was a bad time for startups in this industry. I didn’t know how long I’ll have to wait for a housing recovery so I decided to learn new skills while making buildings to my portfolio. I had some basics learned as a child building plastic kits but now with internet forums full of knowledge I could quickly improve in the areas I wanted. Starting with architectural projects, I cast resin model railroads and wargame scenery and moved on to figurines and finally vinyl toys and engagement ring boxes. All of these small models allow me to test different building methods and learn new things.

What are your go-to tools and materials for building custom toys?

I use a lot of polymer clay (Sculpey) and epoxy putties (Milliput, Green Stuff) on toys and basic tools like a knife and dremel. I often use my laser cutter to fabricate some of the finer details. It helps me build things faster and more precisely, and just recently allowed me to build my first 3d printer which I am going to use for my future creations.

Why do like you working with KidRobot Munnys/Dunnies? What’s the appeal of modding an existing toy over building one from scratch?

Modding existing toy saves a lot of time because I don’t have to create basic body shape every time. A blank figure’s own features create a perfect mix of inspiration and limitations that push me into design decisions I wouldn’t make with a ball of clay and metal wire. That makes it interesting, sometimes challenging and way faster process.

I like Kidrobot Munnys/Dunnies shapes and proportions but I also want to work on other platforms, like Disney’s Vinylmation.

How did you first get into making custom engagement ring boxes? What’s your approach to designing something unique like the Toy Story box or the Wall-E ring box?

It started with box based on house from Pixar movie Up for client from New York. He saw the previous two versions of this house on my blog and asked if I could make it openable to fit an engagement ring. I had many requests for this model as a cake topping, but the engagement ring box was something new so I gave it a try. It turned to be quite popular and appeared on many wedding related websites. I got more requests from people to repeat this object since then but I don’t make the same box twice. Some of them come with different themes so I take the persons interests described in brief emails and merge it with characters from their favorite movie. They either like my concept or we discuss how to improve it bouncing the ideas in emails what sometimes takes few days. Than I start building and solving problems on the go and learning even more.

Can you walk us through a typical custom Dunny build from concept to finish?

It usually starts with idea triggered by film or email from the guy on other side of the world. When I am not occupied by another project, I like to work on it while I’m still excited. I quickly gather some reference photos and start painting or sculpting right away. I sometimes make rough sketch on paper, but most often just work with the figure. When it is going to be just portrait painted on a Dunny I can start the same evening because I have few primed heads ready on my shelf. Sculpted customs needs more preparations and a rough plan in my head of where to cut plastic out and where to add material. With my first customs, there was much hesitation at this stage, now I do it faster and trust my instinct more.

I sculpt with Super Sculpey or with Milliput, depending on what I want to achieve or how strong the part needs to be. Sculpey is very easy to shape and I have unlimited time to sculpt or change things. When the shape is ready, I harden it with a heatgun. I often harden section by section and add details in stages so I can hold the figure without the risk of damaging finished areas. The Sculpey sometimes cracks and won’t stick to vinyl properly, and in those cases Superglue is my best friend. I use Milliput Silvergrey or Superfine for parts with sharp edges or the ones which need to be stronger. It is two parts epoxy putty which hardens to rock hard mass. It adheres very well to everything but it’s quite brittle and much tougher to work with. It also dries in 2 hours so I must be fast. I always get the basic shape by adding layers and sand everything at the end. Finally, the finest details are made of Green Stuff, also two parts compound for precise work.

When sculpting is done, I prime the whole figure with spray paint and finish with brushes. For bigger customs I mask and paint with sprays or airbrush. Whatever does the job best.

I feel the best with small models and fine brushes. Next year I need to leave my comfort zone and do bigger customs with details and accessories made on my new 3d printer.

I see with the Wall-E engagement ring box you used laser cut styrene sheets. Do you often work with CNC machines?

I am following 3d printing since Shapeways started, I even used their service few years ago and it was great. Since then I bought laser cutter, and I could make almost anything with flat parts combined with hand sculpting. I was watching development of Reprap based machines and the quality of prints is finally good enough for my needs. I decided that it is time to put my hands on this technology, so I built my own 3d printer just 2 months ago. It is based on Printrbot plans with parts sourced on Ebay. I was surprised that it works and it was not difficult to make. I am now planning to build second version of the machine, less wobbly and fully enclosed with fumes vented out of my room/workshop. Than it can print me parts while I am working on something else. I will be experimenting with it next year.

What’s the most odd request you’ve had from a client for a custom toy?

I didn’t have any odd requests yet, but I realize I am at the beginning, so bring it on, the more odd, the better 😉 My favourite model is Wall-E. It had lot of details, but the building process was very smooth and I love this character. A full size version is still on my “to do” list, I just need to learn programming Arduino and electronics.

What would you recommend for someone who wants to make their own custom toys? Where can they start? Painting? Sculpting?

Don’t hesitate, just buy the blank toy and start. It is not expensive and it is so much fun. Your skills both sculpting and painting will improve with every toy made, so no need for prolonged preparations, just start practicing by making.

What’s next for you?

I am now planning to build second version of 3D printer so it will be reliable machine. While doing that, there will be more custom toys. I would like to do movie props and animatronics. I am learning electronics in my free time to be able to make things with moving parts, meaby simple robots. There is many things which fascinate me and all involve making, so I will see where it leads me.

Photos Courtesy Michal Miszta

3 thoughts on “Maker Profile: Michal Miszta’s Custom Engagement Ring Boxes”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Show And Tell

Mechanical Dragonfly Automata Kit Build and Review

Time for a model kit build! This steampunk-inspired mechanic…

Its amazing idea.. I also would like to have this antique idea for my diamond engagement ring that i have purchased.

Im probably going to ask sometime in 2013, this might be a cool little add on bonus to use when doing so.

Probably this is revolution and different ideas for surprises. Need to stay connected this guys for another innovative and special ideas and for engaged rings.