Maker Profile: Chris Barton’s Prop Restoration Work

Who do prop collectors turn to after they buy an old screen-used prop at auction?

One of the things we’ve learned in the past year from our conversations with prop makers, collectors, and replicators is that props made for the silver screen don’t really hold up in person. For a variety of reasons–budget and time included–an imaginary science fiction rifle or robot built by the prop department for a movie just has to look good enough on screen to impress audiences or be enhanced with computer generated graphics later. And when these props are pulled from storage and acquired by collectors later on, they might be in even worse condition.

So who do prop collectors and resellers turn to when they want to bring back to life an animatronic Mangalore head recovered from the production of The Fifth Element? A professional prop restorer, it turns out. Chris Barton is one such restorer–he’s an ex-prop maker that runs Alchemy Custom Displays, a UK-based shop that restores props and creates custom display setups for collectors to show them off. When Prop Store of London came into possession of two Zorg ZF-1 rifle props, they went to Chris to refurbish them and replace components that had been lost ten years after the props were originally made.

I spoke with Chris about his career in prop-making and how he adapted his skills building animatronics into a job restoring old props for those who want a piece of movie history exactly how they remember and imagined it.

What’s your background in prop creation? How did you get started making props professionally?

In the late seventies and early eighties I became really interested in movie special effects, and the release of The Dark Crystal really opened my eyes to what could be achieved. Disillusioned with my job as an art director in advertising, I decided to try and get a job in the UK film industry, so in 1985 I wrote to Jim Henson’s Creature Shop in London, and was asked to go in for an interview. This was quite a heady time in the UK film industry as films like Aliens and Little Shop of Horrors and Legend were in production. To cut a long story short, two years later I got offered a trainee animatronics position on The Storyteller TV show.

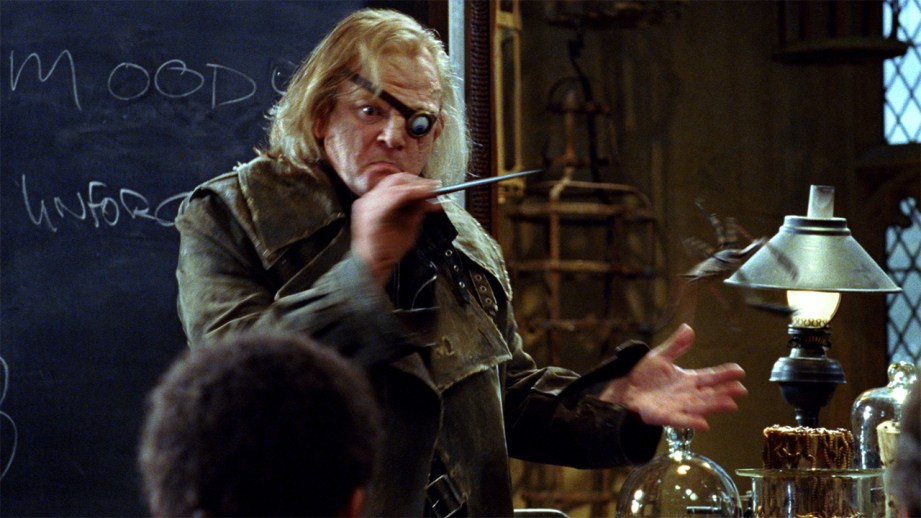

At Henson’s I worked on Teenage Mutant Ninja Turtles, The Witches, The Flintstones and Babe amongst others. After Henson’s, The Fifth Element came next, followed by The Phantom Menace and the Harry Potter series – on all of these films I was involved in the mechanical design and construction of the various creatures. It was a fun time!

Where did you learn your skills? What materials do you typically work with, and what tools do you use in your shop?

As anyone who has worked in the FX industry will tell you, you learn something new on every job. Typically in animatronics every new creature is a first, and though things like eye mechanics and the like are broadly standardized or have a common approach, there is always that initial period of “How are we going to do that?!” As you gain more experience you get better at knowing what the best approach will be… at least that’s the hope!

The construction of a prop or creature can use just about every material going, though fibreglass is perhaps the most common component of a prop, though if it’s a creature then silicon rubber or foam latex is the major material. As such I have to be able to handle everything from steel through to gold leaf, MDF board to oak, rubber skins through to real hair – the list goes on and on. I don’t use any particularly specialist tools, though I do have access to a milling machine and lathe for when parts need machining.

You’ve worked on films such as the Fifth Element and Star Wars building props. What were some of the props you were responsible for and how did you go about building them?

Every film I worked on, I was employed to do animatronic mechanical design. In my time I have been lucky enough to have been involved with the building of, amongst others, Yoda, Kermit the Frog, Mondoshawans, Hagrid the Giant, Dino from The Flintstones, Mangalores, Aragog the giant Spider, Nimodians and Mad Eye Moody. For the build, the script is always the starting point naturally, then the contributions from the director and the various department heads involved. It’s then just a question of coming up with an approach that satisfies all those needs, then adapting and developing them–or starting from scratch again)–as the script and budget requirements change.

How did you end up specializing in creating display bases and stand-ups for prop collectors?

A few years ago I visited the Prop Store and met Stephen Lane, the founder of the company. As it happened a couple of weeks later they acquired one of the many animatronic pigs from Babe, which was in a pretty poor state, so Stephen gave me a call. I took the job on and refurbished the mechanisms, installed a servo controller card so that the head would operate at the touch of a button and mounted it all on a base – and that was the start of what has become a long relationship between myself and the Prop Store. To date I have handled hundreds of displays and refurbishments for them, and of course for many other prop collectors, as the years have passed by.

Your current job brings you in contact with some props that need restoration work. Let’s talk about that. What condition are props in when they come to you?

As you might expect it varies, some are absolutely mint, where as others look like they have been pulled through a hedge backwards. It’s not uncommon for an older prop to be reused for another production, which invariably means someone has slapped a load of paint all over it. Some props have just been sitting at the back of a workshop for years and consequently are filthy with grime and dust. The foam latex used for make-up and creature skins is often in a pretty poor condition, due to the rubber perishing from exposure to sunlight, and the more recent trend of using silicon skins also brings its own set of problems, where the silicon oil leeches out of skin, which in itself can also stretch and distort. On the whole though, most props are well cared for, and are usually in reasonable condition.

What’s your goal in restoring a prop–making it look like the original, like it appeared on screen, or as it was originally built? Where do you feel you’re allowed to take some creative license?

The client often has very firm views on how they want the piece restored. There is often ‘history’ in the condition of the prop, which while it may not be regarded as being as it was when filmed, nonetheless is deemed to add fidelity to the piece. By the same count another client may want the prop restored exactly to its original condition. Either way it can be quite a challenge, and ultimately my aim is to make any restoration work I do as unnoticeable as I can. In fact there is little or no creative license with prop restoration, but that is made up for by the creative freedom to come up with an imaginative display that hopefully enhances the piece.

Where do you go for information when researching a prop restoration? Do you ever contact the original prop builders for details?

The internet and DVDs! Often there is literature, such as a ‘coffee table’ book or magazine (I have most copies of Cinefex, which has been a very useful resource for older films). The Prop Store has a vast library of films and software for screen grabs makes the process very easy to get stills. It can be very hard to reach out to the original prop builders, simply because there is very often very little or no information as to who they were. Obviously a piece that has been built recently can make the original makers easier to find, but many older props can only be attributed to Department Heads at best.

Can you describe the process of the Fifth Element ZF-1 restoration?

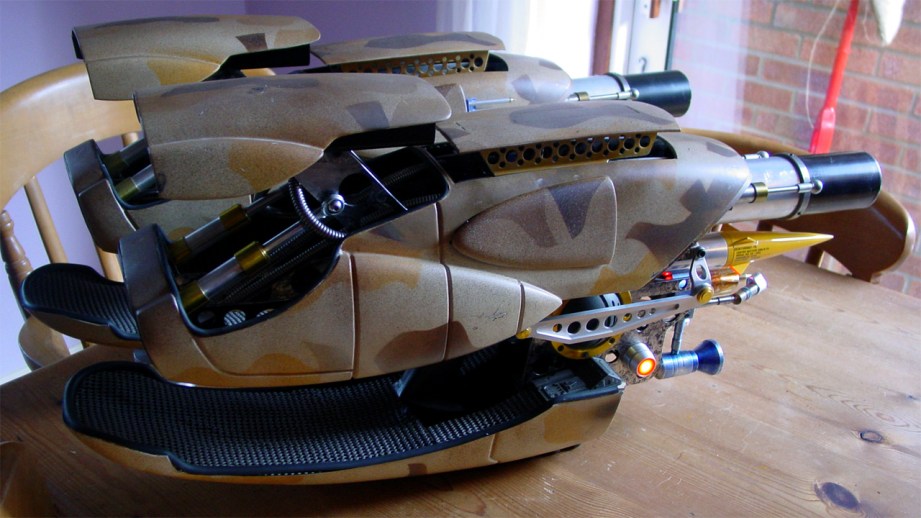

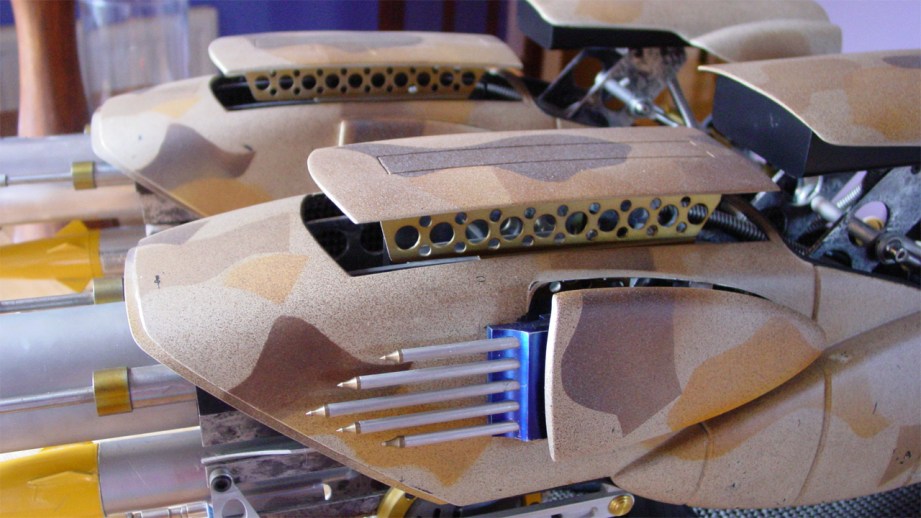

The ZF-1s came to me from the Prop Store. They had acquired a pair of them, just two of the many made for the film, and the brief was to refurbish them to their original state. These particular guns were (very broadly) the flame thrower and the dart/net firing versions. They were in good condition but lacking in a few parts. As luck would have it, the total parts between two of them provided a complete gun, so it was just a case of molding/casting and fabricating the missing components. The entire ‘freezing’ nozzle assembly for example was missing on one of them, so it was just a case of machining the new pieces to match exactly.

I took silicon molds of a number of panels and laid up new ones in fibreglass. Again, having a given part absent on one gun and being present on the other, made it much easier, as there was little or no guesswork involved in making up replacement pieces. It’s quite a well known problem, to guess the size of something from reference with no scale to hand, as many model builders of replica props would no doubt agree.

The biggest challenge was the art finish on the new pieces–the new panels in particular had to blend in seamlessly with the original painted pieces, so trying to deconstruct the paint layering in the camouflage patterning was quite a task. Once the technique was solved, it was then down to matching the coloring. This sounds sort of easy, but it was a flipping headache. T

he final process involved spraying a base layer, then two (matched) patterned layers, with two ‘splatter’ layers between them–five different paint colors in all. The barrel was missing from one, so I cast another–this then had to be painted to match the black anodized scratched original.

In general I was pleased the way they turned out, and now looking at the photos of the pair, I find it hard to discern which parts are original, and which are facsimiles.

Getting access to rare props like the ZF-1 lets you cast molds that prop replicators would love to get their hands on? Is that allowed in the prop building community, or is that property of the prop owner/collector or even production company?

This is an interesting question, and a bit of a grey area. Pulling a mold off a prop takes time and money, so unless it’s part of the restoration process I don’t bother. Broadly speaking, while I always store the molds I make, to my mind, they remain to some degree the property of the respective client. I haven’t yet been approached about providing molded parts for replicas by anyone, but would, under that circumstance refer to the client, who may or may not be happy to let casts go. The production company aspect hasn’t affected me so far, not least for the fact that many production companies fold after the release of the film or show.

What are some recent restorations or custom display bases that you’ve worked on?

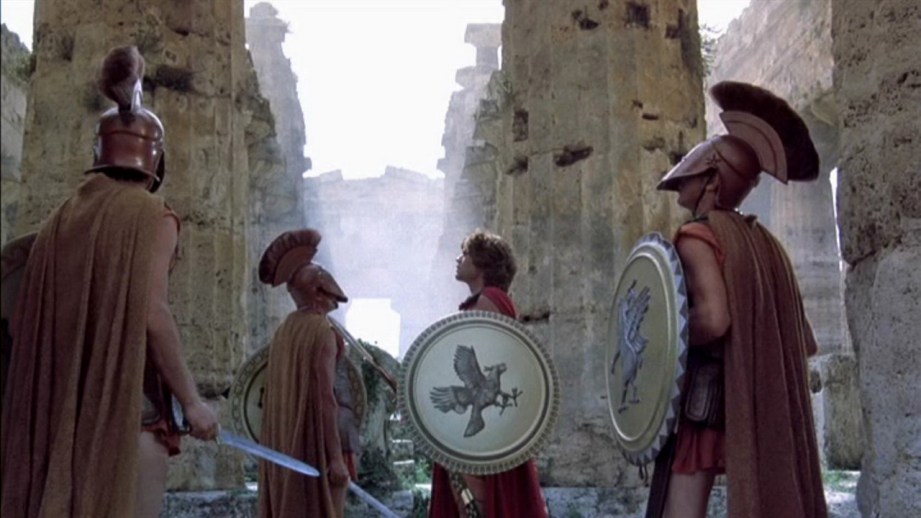

I mentioned old props being overpainted earlier, and that was just the case with Perseus’s shield from the original Harryhausen Clash of the Titans. By using different solvents and about 3,000 cotton buds I managed to strip a thick layer of gold paint off to reveal the original design underneath. It was fastidious work, and not the sort of thing I have the most patience for, but it was satisfying to gradually reveal the original finish.

A large part of my work is modifying mannequins to fit a respective costume, and then put it in a suitable pose. Building a mannequin up is easy, but making it smaller, particularly in volume, can be challenging. Recent work has included Star Trek’s ‘Seven of Nine’, The Chamberlain from Hellboy 2 and Robert Downey Jr’s Chaplin costume from the Chaplin.

What’s the favorite project you’ve worked on while running Alchemy?

The ZF-1 stands out, but doing a mannequin display and base for a complete Indiana Jones costume, whip included, was good fun. People often ask me if I try costumes on, and I don’t. However, I couldn’t resist trying on Indy’s jacket – who wouldn’t!

On balance, the art finishing probably ties with the general refurbishment of a prop. I recently cleaned up a SFX sword from Kingdom of Heaven and taking it from a rusty, broken down state, back to its on screen luster was great.

Are there any specific props you’d be interested in restoring to get hands-on?

Nothing springs to mind. Despite my career (or maybe because of it) I’m not a prop collector myself, but it’s always nice to see a older prop from the seventies or earlier. One of the great things about this job, is that I never know what is coming in next week – it could be a gremlin, a flux capacitor or James Bonds suit!

Images courtesy Chris Barton and Alchemy Custom Displays

4 thoughts on “Maker Profile: Chris Barton’s Prop Restoration Work”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Show And Tell

Mechanical Dragonfly Automata Kit Build and Review

Time for a model kit build! This steampunk-inspired mechanic…

Good interview, I liked this.

I love that not only are there prop replicators and makers but restorers as well. Cool stuff!

I am LOVING the Maker Profiles! Keep them coming! =D

Really interesting interview. I’m also a film & TV prop maker, so I’m guilty of reusing props, but I also spend a lot of time, remaking parts and maintaining props made by other people.