Testing: Smooth-On’s XTC-3D Print Coating

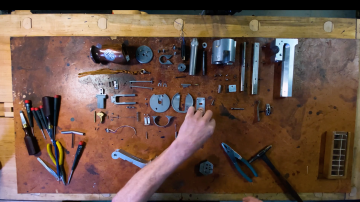

Here’s a behind-the-scenes video for an upcoming Show and Tell product review. Smooth-On, the makers of molding and casting materials we often use, sent us a new epoxy coating for 3D printed parts. We recruited the help of Jeremy Williams to print several things to test this on, from low-polygon figures to complex shapes. To watch along, support us and sign up for a membership here!

30 thoughts on “Testing: Smooth-On’s XTC-3D Print Coating”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

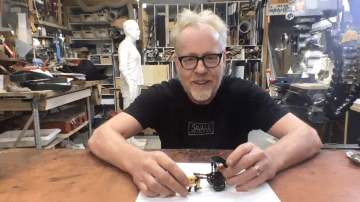

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Normally I really like the content on Tested, but this was like watching Beavis & Butthead, and not in a good way.

I’m not sure what the intent of this video was, but I have to ask: Have you learned nothing from Frank Ippolito? Products like these are messy and potentially dangerous (fumes, heat) and require a little bit of pre-planning and preparation. Kudos for the gloves and eye protection, but not having trash accessible or confining yourselves to such a little workspace is clearly a bad idea. I realize that you’re exploring this much like anyone else might, but wouldn’t it be best to do this in an intelligent manner respectful of the materials and process?

Man.. I didn’t recognize jeremy without a hoody and headphones

Will be interesting to see your results. I painted one print with this so far and had minimal smoothing but good added proctection. I have my eye on devices like this (once they are cheaper)

Well they said this was a “behind the scenes” video for a product review, so I took it as them simply filming their prep-work for that upcoming video. But you’re right that people should always be well-prepared and extra careful when handling dangerous substances.

ok, if they’re just messing around, but that wasn’t quite the impression I was left with. I realize that this is not a final, and I’m not trying to be a jerk — I just have my concerns, especially given what is happening on the video. It’s not a good idea to stick your head into a bucket of epoxy and inhale, unless you’re not planning to live long enough to see your grand kids. Clearly Norm knows this (or should.) Even though this is BTS, it is also branded material, and we have paid a fee for special access to it, so it was intended to be seen. In this case, I think discretion would have merited a different decision.

That’s really all I have to say. I’m sure the actual production video will reflect the better practices that we have seen in the other videos Tested has created over the last few years.

C’mon… 1 good lung full of epoxy fumes is not going to do anything bad to anyone.

after reading your comment I was half expecting a Will in the wood shop type event. It’s not like they were huffing the stuff and handling it with bare hands. My only criticism would be the complete lack of understanding of what this stuff was, pretty clearly just a filler but hey that’s what testing is all about.

I’ve been interested in this product since I heard about it, I can’t wait to see the results!

Man, I really don’t like this player. It always seems to buffer maybe 10 seconds? And then just stop out right. I don’t know if it is a problem on my end, or if I am doing something wrong, but it’s really frustrating…I want to watch these videos lol

I watched all of that and there aren’t even results at the end? What a let down. Not sure videos of two guys that don’t know what they are doing smearing some goop on plastic parts are really worth the membership fee.

Well, It was a behind the scenes. I thought it was alright. I don’t look at the value of the membership on a video by video basis, if you do, you would have to tally the videos that you watch/they have put out and then divide the yearly fee by that. Witch means this video probably cost you $3 or 4 right now, if your going from the start of this year, or for me, it would be more like $0.25.

As far as the safety stuff, what else could they have done? In a typical home setup for the hobbyist, I think that is pretty accurate. When I was first using resin to mould things, i wasn’t even wearing gloves, and would get it on my hands all the time. It wasn’t until I read a lot into the info online that I realised that was bad.

I wasn’t under the impression that the intent was to be a hobbyist. Even if that were the case, caution should be exercised in these presentations. Even a simple, “don’t do this at home” would have been helpful here. As the team has frequently worked with the likes of Frank Ippolito, and has access to some rather prolific people and companies (Adam and Jamie, and the recent, and fantastic, behind the scenes at Jim Henson’s Creature Shop), it would be preferable to see these experiences reflected in the approach taken. Given the sponsors, material and gear, Tested is hardly amateur night…

This stuff kind of acts like a filler of sorts. There are no results at the end of the video because they haven’t shown us what it looks like after the set time. It will come out glossy, and they can choose to sand it down afterwards to dramatic effect.

I thought the exact same thing.

I’m guessing the heat from the curing of the resin can cause the glass to crack if you mixed in a glass cup. I mixed too much hardener into fiberglass resin once and it cured as I was mixing it and got so hot it was actually smoking.

A lot of this has been said, but I don’t mind repeating what’s important.

Get a little more advice from Frank about preparing your work area for disaster. I do not see enough protective layers on that small round table– you need coverage everywhere — I also recommend a small carpet remnant to preserve your present carpet– did I use the word “disaster?” A few drops, splashes or smears and that table is of questionable use. That table is too small for two to work on. I believe I saw the same small measuring cup used for both chemicals as well as the same mixing stick. That is WRONG and you must never do that again. In this modeling form, all “efficiencies” are false efficiencies. I noted Jeremy fussing with his glasses with his gloved fingertips, after he had begun working with the chemistry. Bad form. Especially with a long-cure material and something that can be considered “close” to the eyes. Norm– safety glasses that do not include side-guards are “illusory” safety glasses– ask Adam how many times a chip bounced off his inner nose when machining with glasses on! There should be a standard-issue tall garbage can at the ready for such chemical or even construction projects. When working with unknown chemistry, it is wiser to use a solid tin tray, rather than making one of your own out of the “pinch” method. You never know how strong it needs to be, especially with some kind of material that is to be “painted.” You won’t know how sticky it starts or gets during the time of use. “Well ventilated” in a practical sense merely needs *some* air-flow. You guys appear to be in an office building, either set up a small fan or tun on the A/C for short blast.

I am confused by a lot of the responses. The majority of videos I watch on here, especially when “testing” out products, is just that, testing. This is not a hobby website, instructing you on how to do things. It is a testing website, where they try things out.

Sometimes this may provide helpful information, or direction. Other times it may not. I would understand criticizing their method if it might affect the final performance of the product they are testing, but safety instructions should always be followed if you are attempting to replicate them.

As far as glasses, Norm was going with the 99% safety route, especially considering they werent slinging things around at speeds that could cause ricochet, or applying this material above his head where it might drip at an angle.

I guess we are at the point that there has to be a disclaimer at the beginning of each video saying, don’t be stupid and mindlessly copy us, double check safety instructions and follow them for your own protection. This should at least prevent half the comments devolving to Mrs. Lovejoy yelling “Wont somebody please think of the children!”

I’m not talking about cost, I’m talking about value. Different concepts. I wouldn’t mind so much if there were some results at the end but this video was all buildup and no payoff. That just was kinda annoying because I sat through the whole video expecting to see the outcome at the end.

Ah man 20 minutes of foreplay and then nothing. Love you guys, please don’t do stuff like this without mentioning that its just part one or something.

It’s a behind the scenes video. So not really expecting a payoff with it. Was a brief distraction for me for a few minutes and made me curious to see the full thing. Happy with that.

As a side note, they had enough basic safety precautions I think. Let it go guys. As with everything else your own common sense should be used. If you want to use more protection feel free. But once the basics are covered that should be enough for video purposes.

I’m just waiting for the disclaimers to have to be put on these videos down the road. Hopefully if that happens they will be US only and us europeans won’t have them 🙂

Stop bitching! If you are gonna bitch do it on you tube, gloves should be enough PPE

A couple of sheets of plastic, foil or paper should be enough to protect the table.

the new player is not working at all for me

Yeah it’s wierd, I complained, and then the next day it worked fine. I don’t know what happened, lol

its a real pain in the arse, the old player worked great for me, i must say the site was better with the old corporate over lords

I haven’t been following tested for too long….since maybe November? So I dunno what it was like in the old days, lol. But yeah, I had minor problems with the previous player, but nothing a refresh wouldn’t fix. Like I said, this one was broken 1 day and fixed the next for me……..sorcery?

its still not working for me

🙁

why can we not adjust the quality of the video all my screen does is buffer

It appears to be automatic … I don’t get the old buffer issue but I just noticed that the video quality dropped dramatically. Kind of like YouTube.

am only a kid but I love your work and I love Mythbusters so keep up the good work

Honestly I love Tested #TeamNorm although almost a month without any new ‘Premium’ content kinda sucks… making more prop replicas in Adam’s shop would be great! but this video was good.

Also the old video player worked perfectly and even gave you an option to download the video in 1080p.. while this new player barley seems to work and by that I mean it buffers for like 5 mins then it just stops, super painful to watch a 30min video.