Bits to Atoms: An Overview of Today’s 3D Printing Technologies

Many of you are probably somewhat familiar with 3D printing. Will's weekly MakerBot Mystery Builds, CES coverage of new printers, and other highlights pop up all the time, but now we are looking to delve deeper into how these new technologies work and are related to each other. To start things off, here's an overview of the 3D printing process and methods of printing.

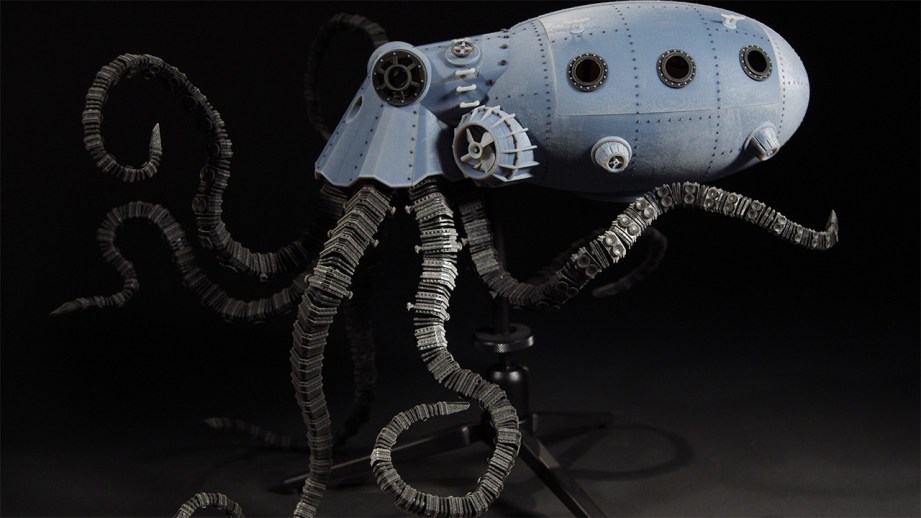

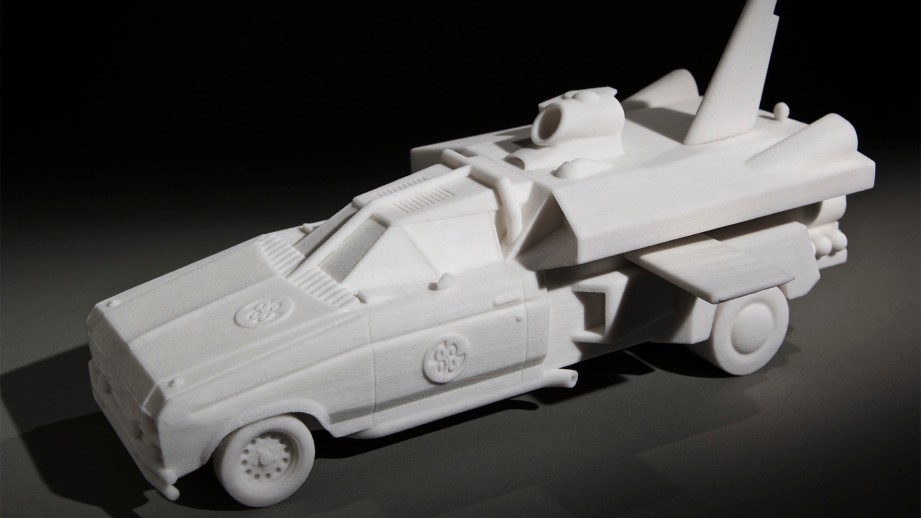

[Norm’s note: If Sean’s name sounds familiar, it may be because you first met him as the winner our first Inventern competition, in which he and the two other awesome finalists flew out to San Francisco to spend a weekend working on Adam’s final build challenge. But we first heard of Sean when he posted photos and videos of his 3D-printed Octopod vehicle project that was his Masters Thesis at NYU. As it turns out, Sean’s expertise is in 3D modeling and printing, and has had experience using various 3D printing technologies and combining rapid prototyping with real-world hardware. Basically, he’s way more knowledgeable than us when it comes to 3D modeling and printing. So I was delighted when Sean agreed to share that knowledge with us and Tested readers. Over the course of this year, Sean will be writing a bi-weekly column on Tested about modern home and professional 3D printing technologies, provide tips on how to get started, and share walkthroughs of his various 3D printing projects. To kick things off, Sean’s first column is a re-introduction to current state of 3D printers.]

Many of you are probably somewhat familiar with 3D printing. Will’s weekly MakerBot Mystery Builds, CES coverage of new printers, and other highlights pop up all the time, but now we are looking to delve deeper into how these new technologies work and are related to each other. For this first column, I want to start fresh with an overview of the 3D printing process and current methods of printing.

Today’s 3D printing is primarily an additive manufacturing technique in which a digital model is translated into a physical object by a machine which ‘draws’ very thin layers of material on top of each other until the object is complete. There is a wide range of machines that print in different ways and materials, including plastic, metal, ceramic, plaster and even rubber.

Up until recently, 3D printing was more commonly referred to as rapid prototyping and/or additive manufacturing. Developed in the 1980’s, it was primarily used in manufacturing industries as a cheaper and faster way to build prototypes. This technology finally reached the consumer-level in the mid-2000’s, mainly due to the hard work of open-source hobby groups such as The RepRap Project. The goal of the Project was to develop and promote an open-source, self-replicating 3D printer and there are many printers based off the RepRap Project. If you buy a kit to assemble, chances are it’s some form of RepRap, in fact MakerBot grew out of the RepRap community. If you want to learn a lot about home 3D printers and possibly build one yourself, this is a great place to start.

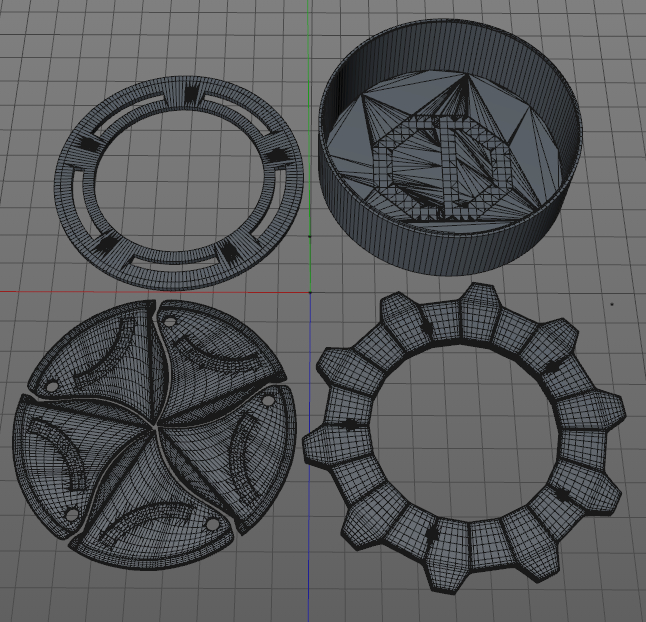

The digital model is typically created in either CAD (computer aided design) which is generally used when mechanical parts and precision are needed or a polygon modeler which are typically used for animation and game assets. Examples of CAD programs are AutoCAD, SolidWorks and 123D Design. Some popular polygon modelers are Maya, 3ds Max and Blender. There are advantages and disadvantages to each and many more options which will be covered down the road. The model can even be created by scanning a real object, but regardless of how it’s done, the model is eventually exported as an STL (standard tessellation language) file which simply describes the surface geometry of the model in triangles. The STL should always be processed through a mesh repair program such as netfabb since during construction it is very easy to create a mesh that won’t print properly due to defects in the mesh. Once again, we will talk about this more later.

Once repaired, the STL file has to be ‘sliced’ into the layers that will be drawn by the printer, one at a time, layer-by-layer on top of each other until the object is completed. The STL is brought into a slicing program where you specify how thick each layer should be (resolution, typically in microns), what type of material is to be used, how solid the finished piece should be (solid, hollow, or in-between), how fast it should print and whether support material is to be used. This all varies based on type and brand of the printer and what software is being used. Really big or complicated models can take a long time to slice, particularly on home printers. The slices are turned into gcode, a machine language used for manufacturing on both CNC machines and 3D printers and describes the tool path for printing.

There are a lot of different 3D printing machines out there ranging from kits to mid-priced prosumer home machines, to crazy-expensive industrial machines. I would say that resolution and support material are the two biggest factors dividing printers. Some may argue materials as well but ABS parts that I have printed on my MakerBot are more flexible, stronger and have better longevity than some parts I have printed on the $500,000+ Objet machine. The difference is the Objet can do much higher resolution and support material that allows you to print parts you cannot on a home printer.

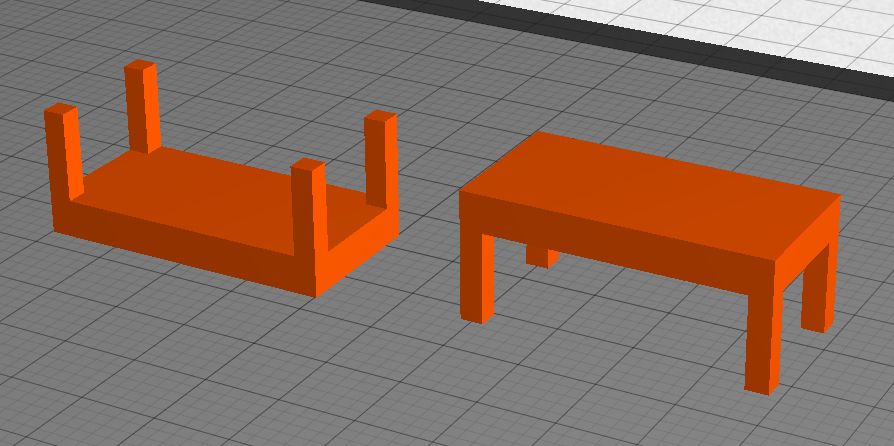

For example, let’s say you want to print out a miniature table. If you print it right-side up on a home printer, it will start with the bottom of each leg, build it’s way up to the tabletop and then run into a problem since there is nothing to print the tabletop on. It’s trying to print in empty space and the print will most likely fail. The high-end machine will have some type of support material that it will build up under the tabletop so there is something to print on. The support material is removed once the print is complete.

Now in this case the best thing to do is simply flip the table upside down so it prints the tabletop first and then the legs. This orientation needs no support so it will print fine on the prosumer and save money on the high-end printer. Prosumer printers do have support material made by either printing extra structures to hold up overhangs or using dissolvable materials. Up until recently I would never use support on my home printer since it never worked very well and would put blemishes on the model surface. For dissolvable material you need a machine with dual print heads and relatively mild chemicals to dissolve it. Great improvements have been made on support generation on prosumer printers and I use them more often as of late.

Now that we have covered how it all works, let’s take a look at the different 3D printing technologies in use today. This is terminology I’ll be referring to in future columns, and that acronyms you may read or hear in 3D printing coverage.

FDM – Fused Deposition Modeling

Thermoplastic filament off a spool is heated and extruded through a nozzle and ‘drawn’ onto a print bed. Most home machines are FDM or technically…

FFF – Fused Filament Fabrication

This is the exact same thing as FDM but can’t be called that due to trademarks. MakerBot, Ultimaker, Cube, Solidoodle, are all FFF machines. Most print with PLA (biofilament made with corn or organics, smells like waffles) or ABS (LEGO plastic).

FFF tends to be the affordable printers with very affordable materials. Prints can go up to pretty high resolution and can be very strong. Resolution still can’t match SLA and other high-end printing and supports can be messy to remove and not as effective as other machines.

3DP – Three-Dimensional Printing

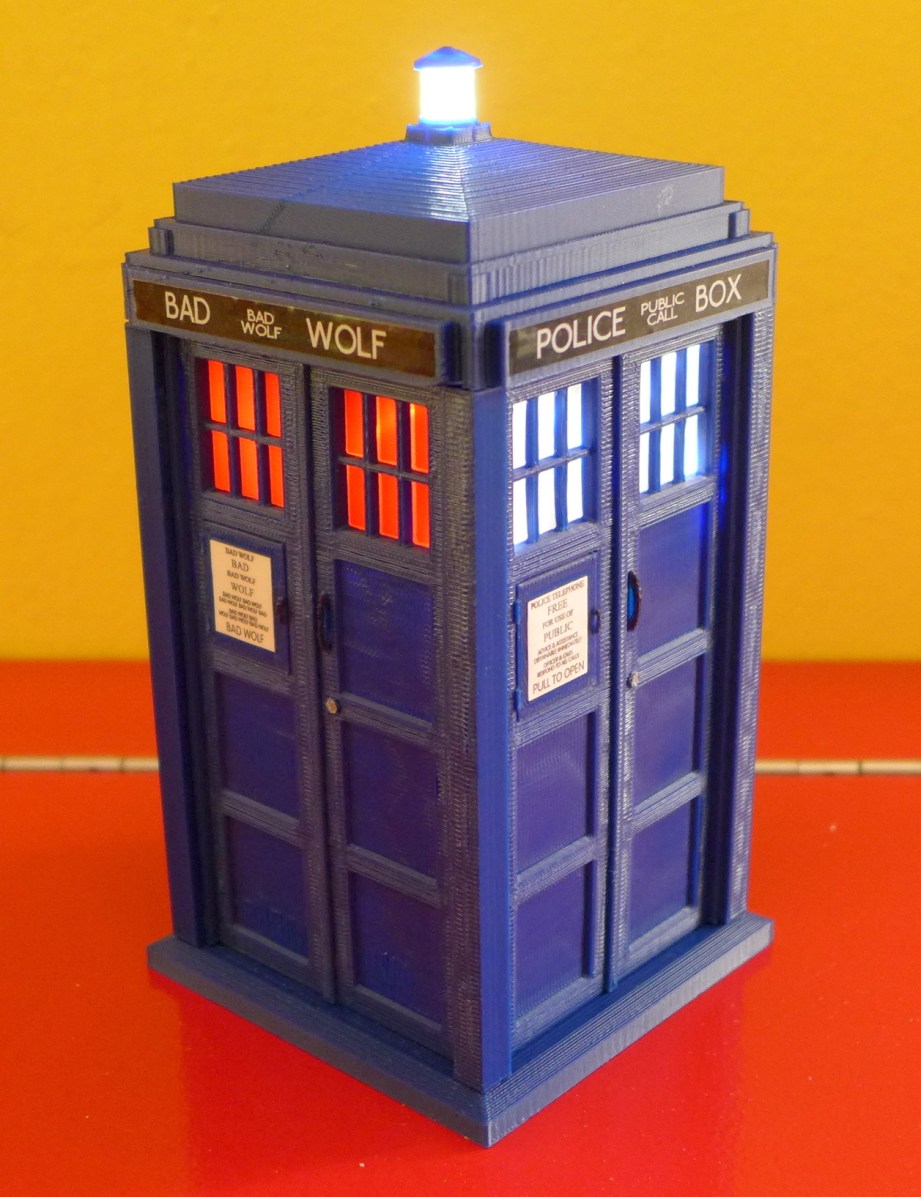

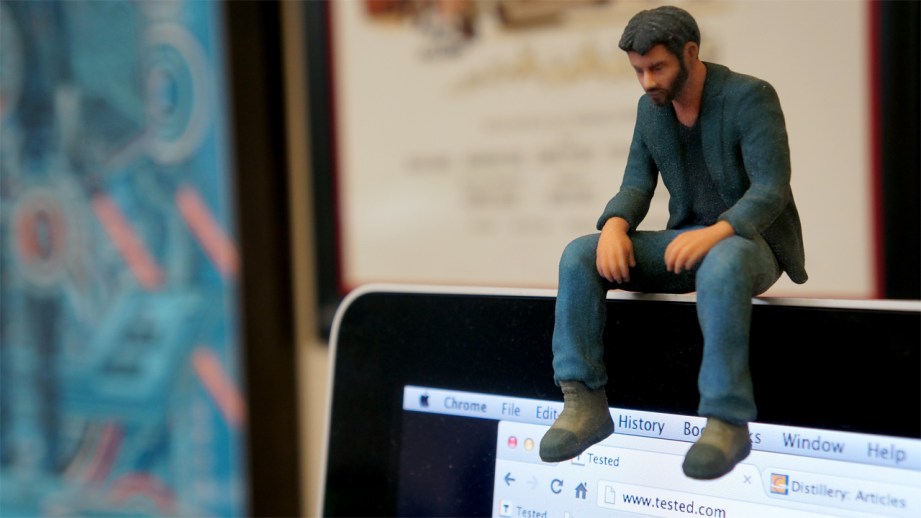

The term for original ZCorp machines which uses a plaster-like powder and a cyanoacrylate (super glue) binder. This type of printer has a print chamber which starts in the up position, a thin layer of plaster powder is laid down and an inkjet head distributes the binder material anywhere the model should be on the print bed. The platform moves down and another layer of powder is distributed and bound. The interesting thing about this method is any powder which is not part of the model acts as the support material. If the model is designed to be hollow, significant savings can be had since any loose support powder can be reclaimed and reused. This is also the only printer that can do full-color, this is what Shapeways uses for Sad Keanu, etc.

3DP is usually the cheapest pro option, does detail pretty well, but not as good as SLA or SLS but can do full color prints. Finished models are very fragile until they are infiltrated which requires them to be completely dipped in super glue. After infiltration they feel like and have the strength of unfinished ceramic.

CJP – ColorJet Printing

This is what 3DP is now called since 3D Systems bought ZCorp. It’s the same thing, although they have announced a plastics-based machine which can also do full color.

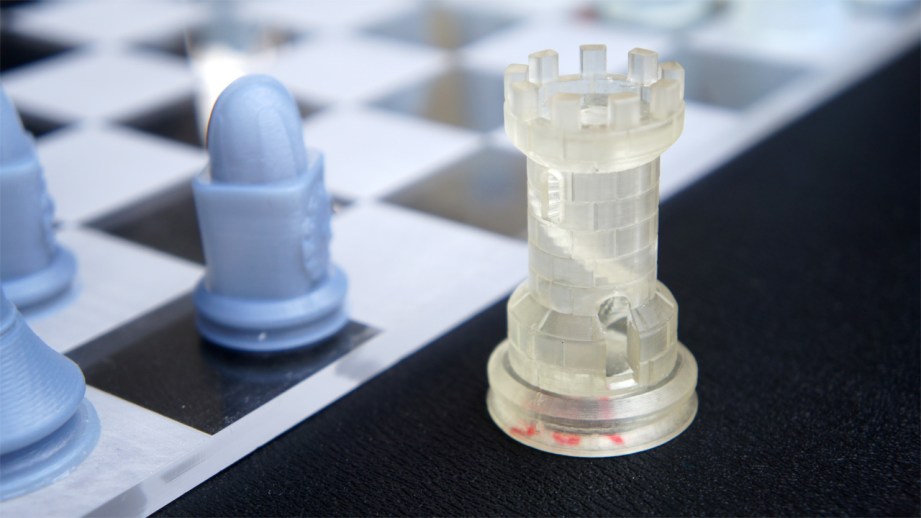

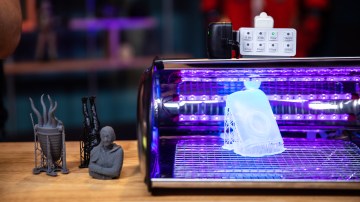

SLA – Stereolithography

The first type of 3D printing developed in the 1980’s by 3D Systems. Uses a laser which ‘draws’ each layer in a vat of liquid resin. Wherever the laser hits the resin it hardens and forms a layer. The object is anchored to a platform which moves in or out of the vat (depending on the printer) as layers are added. Supports are typically small ‘spears’ that can be easily broken off after printing. Some machines require additional UV curing of the model after removal from the vat.

SLA can be very strong and very high resolution but removing all of the support spears can be a giant pain and cause surface blemishes. Most SLA machines are professional versions except for the Form 1 which is a great prosumer machine developed by MIT grads.

SLS – Selective Laser Sintering

The setup is similar to 3DP but uses a laser to fuse a thin layer of plastic, glass, ceramic or metal and loose material still acts as support. Plastics models are ready right out of the printer. Ceramic, metal and glass may need to be fired to further fuse the particles together.

SLS is nice since the support is easy to clean up and most models are ready right out of the printer. Surface finish is still slightly rough like 3DP but can be polished. Details are usually very good and slightly better than 3DP. Plastics are very strong and slightly flexible. This is Shapeways goto tech for most of their prints including the great Strong & Flexible material.

DMS – Direct Metal Sintering

Similar to SLS but directly binds and melts metal powder together for structurally sound and pure parts. I believe this is what NASA was using to make jet nozzles.

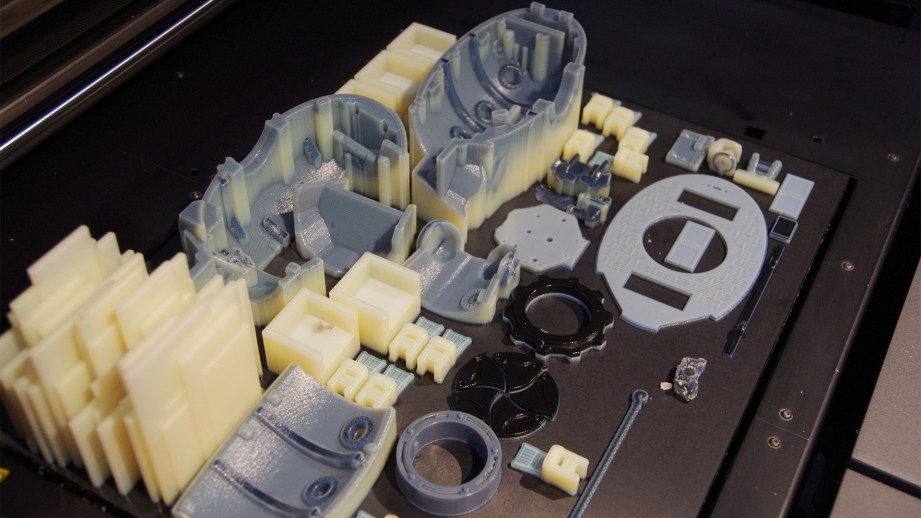

PolyJet

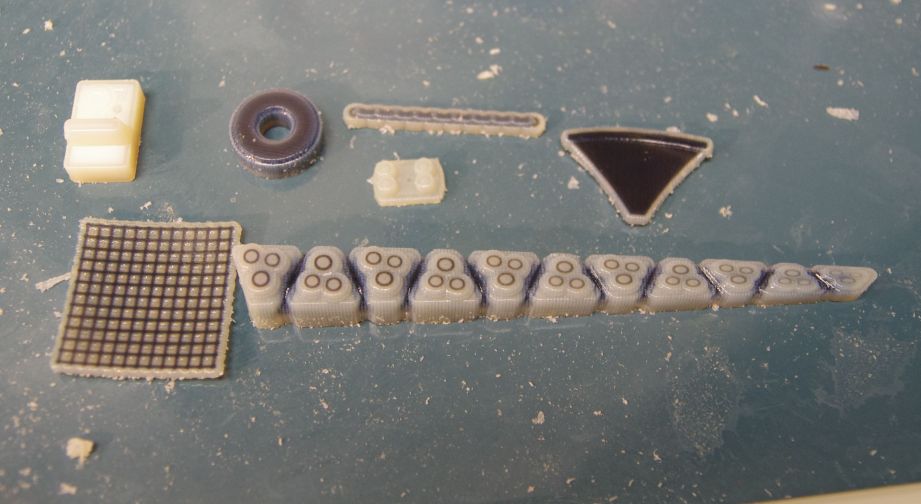

Composite liquids are drawn on print bed with inkjet heads then cured with UV light. Not as messy as most of the other methods but uses a wax-like support material that encases parts that need it. Objet machines were unique in printing multiple materials by using two print cartridges. An Objet Connex 500 can print rubber and plastic at the same time. Or different digital mixes or color and/or hardness at the same time. This is how I made the rubber tentacles for my Octopod and printed rivets and other details right out of the printer.

Polyjet is capable of high resolution, a wide range of materials including rubber and can print overmolds (plastic with rubber modeled to it like your toothbrush). The support material can be a pain to remove, usually starting with a water jet and moving to using mild lye baths, but the end result looks great. Some of the materials do not hold up well over time, but it’s mainly meant for prototypes.

MJP – MultiJet Printing

3D Systems just announced their version of Polyjet which can do the same type of stuff as the Objet. I believe that 3D Systems uses a wax support that melt away when heated. Don’t have any experience with this stuff yet.

Paper

Mcor Technologies uses reams of paper which are laser cut and glued together to make objects. The resolution is dependent on the thickness of paper and full color prints can be done by first printing out each paper layer on a regular printer. Staples is supposed to be offering print services with these in house. I’m skeptical as to how well this will do, although I have seen some prints in person and they were not bad for being paper. Update: please see my full review of the Mcor printer here.

Food

3D Systems has announced the ChefJet which will print in sugar and chocolate. It uses technology similar to 3DP (CJP) and can even do full color in sugar. It lays down a thin layer of ultrafine sugar and binds it with water. For chocolate it lays down a milk/cocoa powder layer and adds cocoa butter to bind it. Pretty cool, but how does it taste? Was Will just being polite?

Hope you enjoyed this overview, we’ll continue to tackle different topics and do some walkthroughs of 3D printing projects over the next few months. And if you have questions about specific 3D printing topics or technologies, please post them in the comments below!

Photos courtesy Sean Charlesworth unless indicated.

26 thoughts on “Bits to Atoms: An Overview of Today’s 3D Printing Technologies”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

Welcome Sean, looking forward to this series! 🙂

Thanks, I’ll try not to screw it up.

I am pretty excited about this feature, looking forward to reading more.

Now that Stratasys owns Makerbot, MBI now calls their tech FDM.

as a reprap person, i’m glad to see this post here.

mayby in a further post you could go down a bit as how FFF works exactly. if you find a easy way to explain it, let us know. i’ve tried to explained it so many times to people and mostly they understand less of it after i’m done.

Interesting read. Coincidentally I just finished watching Paranorman this second and I remember them saying that they 3d printed all the invidual faces etc. Great movie and a superb artistic use of this tech!

I got to watch someone setting up an MCOR machine recently (I don’t remember which model). Each sheet of paper is fed into the main chamber and has PVA glue applied selectively to it, then it is pressed up against a heated plate in the top of the machine to help the glue dry and bond to the sheets below it. It is then cut using a knife (not a laser as above) – essentially a very small, sharp blade akin to the tip of an Xacto knife, that can rotate 360 degrees.

Any parts of the paper that are not part of the model are scored in a perforated grid pattern, so they act as support during the build but can be removed in chunks afterwards.

I’m keen to see developments in home laser sinter or Objet-style printers since they can increase the resolution of home machines significantly.

Sean, thank you so much for this piece. As an educator that is trying to dabble in 3D printing to give my students some exposure to it this really helps fill in some very gaping holes in my knowledge. I look forward to reading more of your work in the future.

Hey bottleworks! I’m on the MB forum all the time, your arms are on my to-do list for the 2X.

Kind of what I’m planning on doing. Addressing all the things I get asked over and over.

I met Brian Mclean, the head of RP for Laika and he gave me some good tips on printing the Octopod. They are doing really cool stuff. They also printed the faces for ‘Coraline’ but used the Objet that I used for the Octopod.

After working in video games I now work for a school as an

on staff designer. The school has recently acquired a selection of 3D printers

and want to start classes this year. My experience leads me to make models very

quickly and over the past year been working out the kinks in modelling. As a

teacher interested in introducing this to a class there may be a bit of a

learning curve to learn.

I suggest getting onto Autodesk’s http://www.autodesk.com/education/student-software

website and looking up ‘3D studio Max’ or ‘Maya’ educators and schools are able

to get any Autodesk product in full for free. From there go through the basic modelling

tutorials which will help get you head around 3D modelling principals and

techniques. The biggest issue I am constantly fixing (and the reason why google

sketchup isn’t great when printing 3D) is that the way a model is made on

screen has no bearing on real word physics.

Good luck with it!

Hello to you too! Nice to see you part of Tested.

Thanks for the post Sean,

I’m loving how quickly 3D printing is going from unknown to

common practice. Although I still have my fair share of miss-prints it won’t be

long before household desktop 3D printing is second nature.

I have a query and some further discussion for you. Every time

I see someone mention 3D prototyping/printing they’ll always use the printed

result as the final model. Complete with single colour (or that weird looking

included powder color) the Z-resolution is always visible and inevitably the

model looks like a 3D print.

After getting past the excitement of printing something from

Maya I’ve started experimenting with taking the model further. 3D printing

should not only be used as a prototyping tool but also as a basis for master

models. For my recent prints I’ve taken to covering them with 15+ layers of

enamel spray paint as well as filling in gaps and sanding the model flat again.

From this I want to take this result as use it as a master that can be cast

using silicone.

I have no hope of sculpting a stormtrooper mask from clay,

no matter how I try there’s no way I could get the thing symmetrical however by

modelling it in CAD and printing it out I have the perfect base for it. I’m

even sure I could vacu-form the 3D print and not need any patching/painting/surfacing

.

Is it a common practice for people to not use their 3D print

straight off the bat as the final? Have you or anyone reading this taken the 3D

print one step further. With such a huge community of makers has anyone modelled

a movie prop on CAD and made a cast of a 3D print, or turned a rapid prototype

into a final piece?

I know that at least one person on the RPF used 3d printing to do full Iron Man armor and then went through the bondo/filler and sanding process to make masters to mold and pull fibreglass pieces from for wearing.

That would be very expensive and labour intensive (I think the guy I saw had won some competition for access to a high end 3d printer to use on the project), but results in pretty amazing stuff. It is not uncommon to see IM helmets made that way, though. Doesn’t get much more accurate.

Really good points that I hope to touch on down the road. I myself am still figuring out the molding/casting end of 3D printing but I have seen the molds for casting 3D printed which is pretty cool. There are two issues I see with using 3D prints as the final product. 1) Many of the materials don’t hold up long-term. My Octopod is a good example, after a few months the whole front end started to droop and now the cockpit lid doesn’t fit right. There are materials that are better than others and they are advancing that quickly, I predict that this won’t be an issue much longer. 2) Cost. Holy cow it’s expensive, this will change down the road as well. I printed my Octopod at the NYU facilities where we only pay cost of materials and it was over $600. If I used a real service that probably would have been triple. Makes it tough to make a profit if you are manufacturing for sale.

I too really like the idea that I could make some Stormtrooper armor on a computer with a printer. I’m also intimidated by the whole body cast/sculpting thing but the bigger problem is my small NYC apartment. No where to even attempt that, but 3D printing is somewhat feasible.

Welcome to Tested, Sean! 🙂

Hi sean, great first article, in your next one, can you please explain how they 3D print sandstone? I get that it is probably in the 3DP way, but is it real sandstone? And if it is, even 3DP doesn’t explain how it is printed…

Looking forward to the next article 🙂

Yes, 3DP is the ‘sandstone’, it’s a plaster-like powder that’s basically glued together. Wish I had a better picture but the main bit is the print head, you can see a color ribbon running into it. The print head lays down glue on the plaster which is laid out in a very thin layer on the platform. The printer simply adds dye (the colored ribbon) to the glue if color is needed (that’s how Keanu and other figures are done). To the left of the print mechanism you can see a line dividing the print bed, the left side is a bin full of powder, the right is the print platform. For each new layer the print mechanism pushes powder over from the left feed side to the print bed. Then it lays down glue, then the print side lowers for the next level and the left side raises up to supply more powder. In the end the left bin will be higher since it’s fed a bunch of powder to the right side and the right side will be lower to accommodate the model. You have to dig it out like a fossil at this point since it’s buried in the powder. Then you blow off all the loose stuff in a cleaning chamber.

Finally the print is dipped in what is basically super glue to bind it all together. SLS works in a similar fashion but with a laser instead of glue, but no multicolor and many prints are ready right out of the printer (minus cleanup).

thx for the amazingly detailed answer, so in other words, a replicator, for example can not print sandstone, and sandstone prints are not actually sandstone, merely a lookalike which feels like sandstone and has the same qualities?

‘Yes’ to all your statements. Other than the FDM machines which use actual ABS or PLA (or other plastic) filaments most machines print in equivalents. So when I print with the Objet, I use an acrylic-like material or an ABS-like material. They have properties (flexibility, tensile strength, etc) that are similar to standard plastics. ‘Sandstone’ is a good description of the 3DP material to put in mind how it feels, weighs and reacts. I find that it’s usually difficult to find out exactly what the materials are made of.

Hey Sean, I am excited to see you as an addition to the crew! So I see all of the aforementioned 3D printing info you laid out; and I was wondering if you or Will or anyone else there have heard of LulzBot(they are out of Loveland CO)? I think it is a similar machine to the Makerbot, but it comes with no enclosure. And from what I understand, their software is opensource… I may be wrong, but I would like to see what you guys think of it!

Thanks again man!

Danny Choo also published a great page on 3D printing and small manufacturing:

http://www.dannychoo.com/en/post/27139/3D+Printer+Reviews.html

Tokyo seems to make this sort of thing easier than NYC, but I think I could find places to do the same sort of thing. In fact I think I’m going to need to.

This is great, I love Danny Choo, didn’t realize he was up to this. Thanks.

Hey Sean, I didn’t know your article was published, Nice job man!

Wow! Amazing!

___________________________

ufo3d.com