Bits to Atoms: How 3D Printing with Paper Works

While the Mcor's printer isn't suitable for all types of models or 3D printing needs, it can accomplish a lot and at an economical price, since paper as a material is pretty darn cheap. Here's how 3D printing with paper works.

When I first heard of the Mcor 3D paper printer that made physical models by gluing individual sheets of paper together and printing them out and that Staples would be using them to offer 3D print services, I was pretty dismissive. But after meeting with Mcor’s CEO, Dr. Conor MacCormack, I am better informed and have a new respect for what Mcor has done. While the Mcor’s printer isn’t suitable for all types of models or 3D printing needs, it can accomplish a lot and at an economical price, since paper as a material is pretty darn cheap.

I met with Dr. Conor MacCormack at the recent Inside 3D Printing Expo in New York and he was able to clear up some of my misconceptions while giving me the full story of the Mcor printer. Mcor Technologies was started in 2005 by Conor and his brother Fintan, both veterans of the aerospace industry, where they had first-hand experience with high-end 3D printers–these guys know their stuff. They wanted a printer that would output quality prints reliably, without the chemicals and high-price materials that most printers require.

Mcor currently has two models: the Matrix 300+ which runs around $35,000 and the Iris which is around $47,000. The Iris is a full-color printer while the Matrix 300+ does straight-up paper, no color. They both have a print capacity of 8.5″ x 11″ or A4 paper and up to 6″ height, which is bigger than most desktop printers. The resolution or layer height is simply determined by the paper thickness, typically 20 lbs. (100 microns) to 40 lbs (200 microns) which is about the same as a standard desktop FFF printer. I asked if they had ever printed with anything really thin like ‘bible paper’ and Conor said it typically doesn’t work very well due to the glue and cutting.

Conor also cleared up the Staples thing by explaining that in Europe (Mcor is based out of Ireland) Staples is much more of a service provider along the lines of Fedex/Kinko’s that would do mass-production printing, binding, etc. Currently, this is mostly in the Netherlands. This makes more sense than the Staples at the mall offering the service, so we may not see Mcor printers in stateside Staples stores.

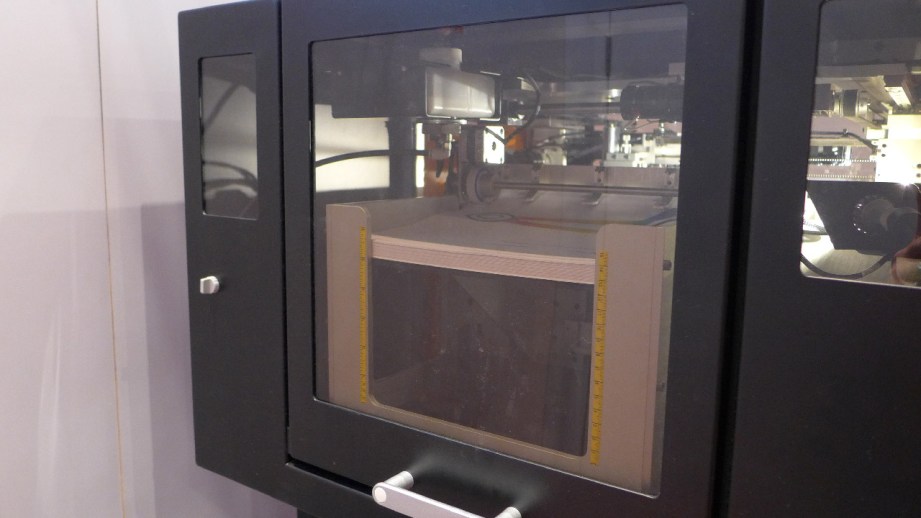

So how does this thing work? It’s a Selective Deposition Lamination (SDL) machine with all of its printing components, including a color inkjet printer, contained within a closed system. Everything happens behind the glass of the box, where the machine basically glues paper together and cuts the model out, layer by layer. Like a plastic 3D printer, software first slices the 3D model based on the thickness of the paper being used. If printing in color, it will also take any texture information and assign it to each sheet.

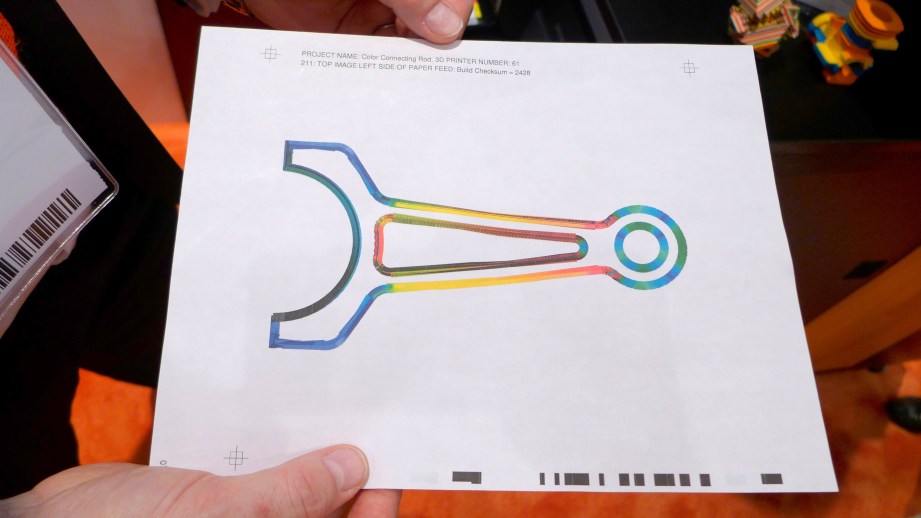

Regular 20 – 40 lbs paper is run through a modified Epson printer using ink that Mcor developed. A laser printer or regular inkjet can’t be used since toner and standard ink does not penetrate the page–which would create thin white bands in the finished model. Mcor had to design an ink that would do the opposite of what you normally want, and soak through the page so the colors are saturated. The printer uses really large ink cartridges, which you can see sitting on the print table in the above photo. The print will also have a certain amount of bleed to allow leeway for cutting.

Each page is barcoded to mark its place in the queue and if any sheets are found to be missing or out of order, the printer will pause to allow you to fix it. There are also alignment marks which are read to ensure each layer lines up properly. Once all the pages are printed they are stacked in the feeder to prep for printing.

The barcode reader checks each page for order and alignment. The print head then puts down a thin layer of glue on the print bed and the first sheet is aligned and pulled into place. The print platform presses the pages upwards against a heated pad to ensure proper bonding.

A tungsten-carbide cutter goes around the outline of the model and then scores the surrounding blank paper so it can be removed when the model is finished. I initially thought this was laser cut but Conor said that process would scorch the paper too much. The tungsten-carbide blade is rated for approximately 7000 sheets of paper before a changeout is needed. Glue is lightly applied to the paper surrounding the model so it can be removed easier, while a more substantial amount is added to the model area. The process continues until all the sheets have been used and the model is finished.

Here’s where it gets fun. The block of paper is removed and the ‘weeding’ begins where you break off and pick away all of the surrounding support paper. As someone who likes sorting LEGO and peeling the clear protective covers off electronics, this looks deeply satisfying and I was saddened that they had no demos for me to dismember. I wonder if papercuts are a danger? This may seem like a pain but many other printers have support material clean-up and most is much worse than this and require special machines. However, this does demonstrate a weakness of this printer: it would be pretty easy to print something that would trap support material in places that would be difficult to remove. In this case I would just keep that in mind while preparing the model, maybe even breaking it into multiple parts to be assembled afterwards.

The other neat thing about this printer is even if you aren’t printing in full color or if you have the Matrix 300+ which does not do color, you can still load any color paper you like to make your model pop.

I was impressed with the level of detail that the Mcor printer was able to capture, especially when combined with color output. The models felt solid and seemed pretty durable although I could see how the layers could start to peel with lots of handling. The color is detailed although somewhat muted on models right out of the printer. The solution to both of these problems is to use a sealant on the finished piece which makes the colors pop and makes a more durable model.

I stand corrected on my previous, uninformed view–I think a lot of thought and work went into the Mcor printer and I really enjoyed learning more about it. Mcor’s approach to 3D printing is different–not a bad thing–and the price puts it in the range of professionals and institutions that can’t afford a $100k+ machine. It’s not going to fit every users needs but will work well for most. It’s also nice that it has an eco-friendly angle since there’s not too many other printers that have materials that can be recycled easily and some that are outright toxic. I don’t see the ‘weeding’ process to be an issue seeing as how many other printers require supports to be cut off, melted off, blasted off and/or chemical-ed off. I think the Mcor would be great for schools and I would love to see them develop a cheaper, smaller, desktop version for home use. I think there’s a lot of potential here.

8 thoughts on “Bits to Atoms: How 3D Printing with Paper Works”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

THAT IS SO COOL

That is neat! Did he mention the cost of a single figure print?

The way Conor was talking, it doesn’t sound like there is a major outlet using the Mcor in the States. The Staples site is Europe-only right now, you can check it out here.

great stuff

I checked out the staples website and a figure like the head could be anywhere from 200-600 euros.

I really like the “mechanical” aspect of this printer, in that you can see a lot of the parts, and they move, etc, unlike a lot of the other 3D printers that mostly occlude the inner workings. Very satisfying to watch in action.

My guess is that it’s meant to take on the other full colour printers, namely the 3D Systems ProJets (prev Z-corp). The price for the machines is about the same, and the Projet material was also comparatively cheap (compared to other 3D printer materials). MCor material prices may be cheaper, but the build time is longer than the Projets. Both material have good resolution but are mostly for “sculptural” parts – i.e. not suited for creating direct prototypes of functional parts.

Presumably this same process could be used for other materials than paper, think sheets of metal, plastic or possibly veneer.

This is really neat though, I like the sorta wood grain look that brain has.

That is pretty darn awesome. Hopefully hobby grade versions come out at some point. With people using single page cutters like the cameo silhouette to cut pepakura files, I can’t begin to imagine all the crazy cool stuff that would get made.