Tested In-Depth: Ultimaker 2 3D Printer

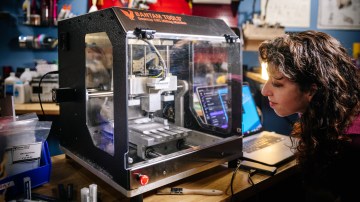

Interested in 3D printing? Our rapid prototyping expert Sean Charlesworth has been testing the Ultimaker 2, and sits down with Will to review this new printer. Its prints are really great! We discuss how the Ultimaker 2 compares with other FDM printers and what you should look for when researching and shopping for a 3D printer.

23 thoughts on “Tested In-Depth: Ultimaker 2 3D Printer”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

If you want really good adhesion I find that making a solution comprised of 2 parts water to 1 part white glue, then applying it to a heated bed at 70°C, letting it dry, and then printing leaving the heat bed on works really really well. I use that solution to print PLA, ABS, NYLON, and other materials without an issue.

Also since when 1.75mm filament became the norm? 3mm filament is widely available, and almost all “experimental” filaments (like laywood, bronzefill, nylon, etc.) are only available in 3mm spools.

The Ultimaker 2 is what I would get for work – I know a number of university labs and startups that have one and they’re all happy (and often prefer it over the Makerbots).

Privately I couldn’t justify the price, but I now just got a Reprap-based Prusa-i3 kit from AliExpress (Shenzen-based seller) for $290 including shipping and 2 spools of plastic. I was positively surprised how good it is: recirculating linear ball bearings throughout, polished steel rails, laser-cut acrylic frame, with a 20x20cm heated glass bed, LCD+turning knob (similar to Ultimaker), print from SD without PC. The electronics are based on Arduino+RAMPS 1.4 so it’s easy to upgrade. It already has all the ports to connect a second extruder as well. It took 2 afternoons to put it all together. Switched it on, and first print worked straight away. Cura supports this type of printer by default as well.

Print quality is as good as Makerbot or Ultimaker I would say – the prints at 70mm/sec and 0.15 layer height look really good. It can go faster (moves up to 150mm/sec). I tried printing PLA, ABS, Nylon and FilaFlex. PLA works perfectly every time, and the parts are accurate within 0.1 mm. ABS was almost always perfect (one part I printed was problematic with warping, all the others were fine). Nylon worked, but some more warping problems than ABS – probably needs a closed-off build volume to get it right. The FilaFlex was a bit tricky, it’s extremely soft. But with very slow feeds it worked and turned out perfectly. I’m now upgrading to an E3D hotend which will hopefully improve it – as it’s a standard RepRap design there are plenty of upgrades available.

I’d highly recommend these kits for people who are not scared of putting kits together – it’s by far the cheapest way to get into 3D printing, and you get a really nice printer. They also have delta-arm printers for the same price which look really cool. Maybe Tested could do a feature? Happy to give you more details 🙂

I have a Ultimaker ‘original’ and after 3 years of almost daily use it is still going strong.

Had to replace some belts and occasional clean the nozzles but that is standard maintenance. What is really great is the speed. It goes fast! For best balance between speed and quality Cura allows you to set different speeds for infill and the outer layer. I often use 150 for the infill and 50 for the outer perimeter. This dramatically reduces print time while maintaining a very good visual quality. I like to tinker and tweak, but after a while it is just pressing print. Compared to a Makerbot which i often used also it is much more reliable.

My cronies and I are mulling the idea of getting a 3d printer for printing gaming miniatures (mainly starships). None of us have any experience doing 3d printing, and would prefer something that is as close to just working correctly on a consistent basis without a lot of fiddling as possible. We are ok with having to assemble from a kit to keep prices down. Is there a good quality kit at a reasonable price out there that would meet our needs? 2 grand is a bit out of our price range for what amounts to a toy for making toys for us at this point.

Wouldn’t it be awesome if you could print in fill at a lower resolution than the outside? Doesn’t only the outer skin need to look nice?

You can kind of do this with Simplify 3D, you can specify how often it will print a layer of infill. Although pushing this too far will compromise the strength.

I’ll be posting a full write up with pictures soon, but here’s the robots. .15mm – .1mm – .06mm

I’d be interested in a full review of the Flashforge Creator Pro and how these two compare. I’ve been looking at 3D printers for a while, and the Flashforge seems to be well reviewed but not given a lot of notice when it comes to options.

Do you have any experience with the MarkForge Mark One?

I’ve got it here. I really like the CAD precision and strength and durability of the prints, but it’s my first 3D printer and starting out on a Pro printer is hard.

For people asking why the Ultimaker is so expensive: It’s fast and accurate, durable, servicable and has a big community. Having built 2 (and a half) RepRap style printers myself and used many different other machines, I would probably start out getting an Ultimaker instead (especially being from europe).

With 3D printers i think its very much the same as with quality hand tools, sure you can use cheap side cutters or screw drivers, but if you want something that lasts, works great and consistent everytime, you gotta invest a bit.

Also for a comprehensive printer test: 3D Hubs (Cloud 3D printing platform) is a great resource https://www.3dhubs.com/best-3d-printer-guide

Laywoo-D3, ColorFabb BronzeFill and Taulman Nylon 680 are all available in 1.75mm. I don’t know of any filament not available in 1.75. The industry in general is moving away from 3mm to 1.75mm, but for now almost all filaments are available in both.

I have seen the MarkForge and talked to the designers in person – it is very, very cool. I was particularly impressed with the software that allowed you to control the different material layers. I have not got to use it first-hand. I don’t know if I would have bought it as my first printer. I may suggest getting a second, cheaper printer that will let you mess around and get the feel for things or even try parts out on. I know that sounds silly to prototype the prototype but I’m sure the MarkForge filament is not cheap, and the parts it makes can be final-part quality.

Yes, @Joo is correct. And just to clarify for everyone, I am in no way saying cheaper printers are crap – there are a lot of great printers out there. However, you’ll often see statements like, ‘it’s a great printer once you do A, B, and C’, meaning that there is a fair amount of tinkering to do. I like tinkering and built my first printer, but my main interest is in designing and building things and I don’t have the time to tinker (this is also the reason I haven’t had my hands on a ton of different printers) so I need something that is as close as possible to ‘it just works’ out of the box and is reliable with good tech support. The Ultimaker offers that and is part of the price. When buying a printer, ask yourself what is the purpose? To explore a new tech, print out cool stuff you find, design and print your own creations?

can you please start doing the print the mystery series again? i loved that.

I just saw that Hobbyking now has a small 3D printer “Mini Fabrikator Tiny Boy” for only $179! It’s quite small (8 x 8 cm) and PLA only, but for that price it’s a bit of a game changer if it works at all – cheap enough to try it out without a large financial risk. According to the description it is “ready to go”, not a kit. Would love to hear if anyone has had any experience with it.

Just to clarify, my Boss just put it on my desk one day with a look on his face that said: “now go make me something pretty”.

It’s really not the 3D printer to start with when you’re a noob, but I’m starting to get the hang of it. The parts you make are indestructable! But the nylon isn’t a good filament to print the pretty things. So this thing is pure function and durability.

In the video Sean mentions that the Ultimaker 2 is also available as a kit, but I can’t find this on their website? Did I hear him right?

Just the Ultimaker Original+ is a kit: https://shop.ultimaker.com/product/52/UltimakerOriginal

Hi, how is the ultimaker 2 for printing with flexible materials (ninja flex or filaflex)? Because what make me suspicious is that it has the extruder in the back…

Good question. I got a roll of the Ultimaker flex filament, but discovered that it was tricky, so didn’t get to try it yet. From my understanding it’s a mixed bag. While feeding from the back does prove challenging, the wider diameter filament works well for flex materials. Ultimaker recommends a modded extruder that you can download from Youmagine if you want to do flex.

Perfect, thanks, I’ll have a look to the extruder on Youmagine 🙂 … Just another question, what do you think about the Leapfrog Creatr HS (of course comparing it to the Ultimaker 2)? And there would be any chance to see a Tested in depth of the Leapfrog Creatr HS and/or the Makerboth replicator 2/2x, or a comparison between these 3 printers? Many thanks 🙂

Have not had a chance to try the Leapfrog. The Rep 2 is a solid printer for PLA, but they discontinued it, I would not buy any of the current gen MakerBots. I own a 2X and while I have it printing reliably and well for ABS and PLA, it took a lot of work and add-ons to get it there – would not buy a new one.

I really like the Ultimaker 2, but thinking about buying a 3D printer in a near future and willing to have the opportunity to print also with flexible materials as ninjaflex or filaflex, I was also having a look to the leapfrog since they have the feeder on the head instead of the back as the Ultimaker has…