PREMIUM – Ask Adam: Tiny Apartment, Big Sanding

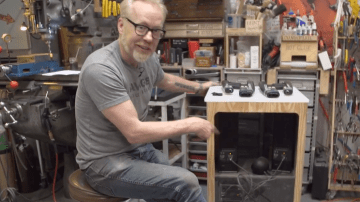

Every week, Adam takes a question from the Tested Premium Member community in the comments section below or on social media (tagged #AskAdamSavage) and answers here. This week, Adam talks about ideas and tools for cutting big materials in small spaces.

23 thoughts on “PREMIUM – Ask Adam: Tiny Apartment, Big Sanding”

Leave a Reply

One Day Builds

Adam Savage’s One Day Builds: Life-Size Velocirapt…

Adam embarks on one of his most ambitious builds yet: fulfil…

Show And Tell

Adam Savage’s King George Costume!

Adam recently completed a build of the royal St. Edwards cro…

All Eyes On Perserverance – This is Only a Test 58…

We get excited for the Perserverance rover Mars landing happening later today in this week's episode. Jeremy finally watches In and Of Itself, we get hyped for The Last of Us casting, and try to deciper the new Chevy Bolt announcements. Plus, Kishore gets a Pelaton and we wrack our brains around reverse engineering the source code to GTA …

Making

Adam Savage in Real Time: God of War Leviathan Axe…

Viewers often ask to see Adam working in real-time, so this …

One Day Builds

Mandalorian Blaster Prop Replica Kit Assembly!

Adam and Norm assemble a beautifully machined replica prop k…

House of MCU – This is Only a Test 586 – 2/11/21

The gang gets together to recap their favorite bits from this past weekend's Superb Owl, including the new camera tech used for the broadcast and the best chicken wing recipes. Kishore shares tips for streamlining your streaming services, and Will guests this week to dive into the mind-bending implications of the latest WandaVision episod…

One Day Builds

Adam Savage’s One Day Builds: Royal Crown of Engla…

One of the ways Adam has been getting through lockdown has b…

Making

Adam Savage Tests the AIR Active Filtration Helmet…

Adam unboxes and performs a quick test of this novel new hel…

Making

Weta Workshop’s 3D-Printed Giant Eyeballs!

When Adam visited Weta Workshop early last year, he stopped …

One Day Builds

Adam Savage’s One Day Builds: Wire Storage Solutio…

Adam tackles a shop shelf build that he's been putting off f…

I love watching Adam age stuff, but it’d be awesome to see how he’d change the technique on something that gets used and abused, like an impact driver, or the handle on a power washer.

I might be able to lend SOME anecdotal advice for. A couple years ago I built a Crib in the room that would be my son’s nursery. I live in NYC. This involved 10′ long maple 2×10’s in a room that was… less than 10 feet long. I had to do initial cuts with the door open so wood could be out the door into the kitchen. It was bad. My solution was sub-optimal for a long term solution, but perfect for short term. I encased the entire room in a plastic bubble, including over the door, to keep teh room I had already painted from being TOTALLY coated in sawdust (it was still bad). I had a window open with the fan blowing out, and I wore a facemask. This made it bad, but bearable, when using the circular saw and router. For sanding I think it all worked VERY well. I used a Milwaukee Random Orbital Sander, with a vacuum hose connected to a shop-vac (well, actually to one of those $20 home depot shop-vac tops you put on a big bucket. I had one die that I had to replace, but I think for the apartment living I have, it was perfect.). The dust was a non-issue for that part, and it was able to take off a lot of material in a very controlled way. I used a plane and then sanded to get joints smoothed down to flush, and that also worked like magic once I got a hang of it.

Initial cuts, before I plastic bubbled the place with shopvac I used to clean after every group of cuts and at end of each day, and of course for the sander.

The legs are 3 1″ layers of wood, planed and sanded smooth. A cheap plane that I sharpened and the RO sander worked like a charm.

This is just AFTER I learned about what happens when you drip new shellac on shellac floors. You can also see the edge of those sandwich-legs again.

A belt sander with a shop made stand might be part of the solution. Several examples can be found online.

Hey Adam,

For those of us who have small studios/workspaces, what are some tips for organizing your workspace? I have designated areas for all sorts of tools and materials but as soon as I start a new project it looks like a tornado ripped through my studio! Any advice? 🙂

There might be some cool solutions in this photoset of Tested-readers’ shops that were submitted following Adam’s 2016 Maker Faire speech. 🙂

https://mdvip-tested.md-staging.com/art/makers/573466-photo-gallery-creative-workspaces-testedcom-community/

If you need to take 1/4″ off of something then you probably don’t want a sander.

Hand planes and rasps take up little space and make little noise.

Track saws take up a bit of space and make ungodly amounts of noise but when plugged in to a HEPA dust extractor they are more than clean enough to operate in a living room.

For large amount of materials hand planes are the way to go, there are all kinds available and they work brilliantly. You can also do the same thing with a VERY sharp wide chisel, but a plane is a magical device and sounds exactly what they questioner is after as long as they are working with wood or something wood like.

I’ve kind of notice planes aren’t as common a tool in the US, I’ve often seen comments about people, even with a lot of woodworking experience coming to them late. As a European pretty much the first tool I ever got shown how to use as a child was a plane(since they are safe as tools get really) and I always find it weird when people haven’t come from a woodworking tradition where they are common.

How did tested.com come to be and how did Adam Savage fit in to that equation in the early days? Who was the chicken and what was the egg?

Tested came first by about two years. This site was created by Norm and Will in 2010, as part of a company called Whiskey Media, based in San Francisco.

In early 2012 Whiskey Media was sold, and the different sites ended up with different owners. Tested ended up with a company called BermanBraun (which later split and became Whalerock Industries), a Los Angeles based production company that had a partnership with Adam and Jamie for producing TV content (they made a special together for Discovery called Dangerous Toys and a tv-show called Unchained Reaction).

BermanBraun figured that since Tested had a fun, experimental approach to technology, and were based in the same city as Adam and Jamie, they were a good fit and brought them onto the site in late spring 2012.

A nice bonus for hand planes: If you’re using nice untreated wood (A nice cherry or maple for instance), using that hand plane = PERFECT wood for smoking some stuff on the grill!

In my experience for small apartments getting to know hand tools like hand planers, rasps, and hand saws is invaluable. They are relatively quiet and not as messy, and with practice are very precise. There is some learning involved, but there are lots of great resources out there on youtube and in books, etc.

I have a very small basement shop where I’m molding, casting and building resin studio-scale miniature replicas and one of my go-to tools is this disk sander from Mico Mark:

https://www.micromark.com/10-Inch-Variable-Speed-Disk-Sander

Attaches with a “C” clamp to any sturdy workbench or table top and with the shop-vac hose attached takes up exactly ten inches by eighteen inches of counter space:

This older version of that disk sander has lasted 10+ years and is a real workhorse in my shop.

and if the plane is tuned well and sharp, a cut surface is way better than a sanded one. also worth investing in: card scrapers and gooseneck scrapers.

or, to be more general: depending of the material, surface finishing may not require sanding at all.

https://www.gamut.com/p/combination-belt-disc-sander-42-in-belt-lg-corded-power-source-MjA5MjY4?gclid=EAIaIQobChMIxuG4lq7H3AIVhICfCh0sSgPREAQYAiABEgIWk_D_BwE

I used one of these in my small apartment with carpeted floors for years. It’s relativey light and small so you can move it around as needed. Plus it’s got a hookup for a shop vac on the disk so dust isn’t a huge issue.

I know this isn’t necucisarlily a question, but I feel as if i need to thank Tested, and Adam Savage in particular. Im currently in my senior year of high school, and I’m doing great, but i can only credit this to this incredible organization. Throughout my high school career, I’ve faced some pretty daunting depression, it broke me. I ended up falling so far into this hole id dug for myself that in the spring of my sophomore year, I attempted suicide. I say this not for sympathy, but to illustrate a point. The point of how deep and broken I was as an individual. After this event it was painfully clear that I was no where close where I needed to be as a person, and as a result I spent a lot of my time doing nothing, left alone with only my thoughts. Those of you who have dealt with depression know that this can be a very dangerous thing. This is where this site came into play. One day I was just browsing youtube, and I came across one of Adam’s One Day Builds, the Hellboy sword. Seeing Adam problem solve and figure out how to make things in an incredible way, and just the joy he got from making this sword from something he loved. Here’s the thing, I cannot put into words how this simple build video changed me. It brought to my attention to the world of prop building, and gave me a new sense of purpose to a degree. But not only that, and I know this may sound strange, but watching all of the one day build videos, it made me feel like I knew Adam Savage personally, like he was a friend, one I desperately needed. It was so captivating to see him make these amazing things, and seeing him so happy when he succeeded, it inspired me. Seeing this video may seem incredibly minute to some of you, and I can’t blame you for that, but one thing most people don’t understand, is when you’re at your lowest of lows, the littlest of things can give you that glimmer of hope. Through the summer of my sophomore year I spent hours upon hours in my room sculpting, model making, and just creating with whatever I could get my hands on. In all honesty, I don’t think I’d be here today if it wasn’t for that one video, that bit of inspiration, that thing to get my mind working again. I owe who I am today to this incredible organization, all the creativity it inspired, and motivation and empowerment it gave me when I needed it most. And if by some miracle Adam Savage reads this, I only have one thing to say. Mr. Savage, I cannot thank you enough for what you have done for me as a person. You have given me the greatest gift I have ever received: the spark of creativity and drive to make things. This site, this group of people, changed my life, it is because of them that I am here today, and that I can proudly call myself a maker.

I use a small Performax disk sander from Menards in my apartment. Does the job, with not much dust. It also has a dust port for a shop vac, but I haven’t found the need to use it yet.

I like the flexibility of the Rigid Oscillating Edge Belt sander… You likely will want to come up with better than the built-in dust control. https://www.ridgid.com/us/en/oscillating-edge-belt-spindle-sander

As a Blundstone boot user myself I’m very curious as to how many pairs you have worn out Adam. And do you store the old ones?

have a look at the kitbashing vid just posted that wee little machine could be ideal for you I think

All the responses to this have been wonderful! I’m in the process of making a miter box that will work with those saws that cut on the pull, as mentioned. Also, embarking on switching to foam to create molds and seeing what I can work with there.

I have a 1inch belt/5 inch disc combination sander and have found that a modified grinder shroud is great for reducing dust.