Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: STAR WARS AND THE POWER OF COSTUME

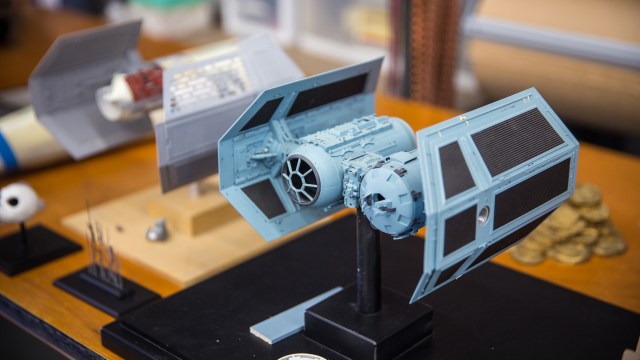

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out at its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8452

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8453

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8457

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8460

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8461

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8462

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8463

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8465

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8467

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8470

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8472

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8474

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8477

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8479

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8481

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8482

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8484

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8488

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8491

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8492

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8496

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8503

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8505

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8506

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8510

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8511

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8512

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8516

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8519

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8521

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8523

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8525

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8528

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8529

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8532

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8549

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8551

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8535

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8538

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8539

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8544

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.

Photo Gallery: Star Wars Costume Exhibit

Photo Gallery: img_8450

I’ve returned from vacation–two weeks of roadtripping to Canada and back and that took me through seven states and two provinces. Along the way, I tried to stop by as many interesting places as possible, including science museums and art galleries. During a lunch stop in Seattle, I made a point to visit the EMP Museum, where I had previously geeked out over its collection of sci-fi movie props. One current exhibit features costumes from the Star Wars films–the first stop in a 12-city nationwide tour. The exhibit was lovely, and a good complement to the recent Star Wars Costumes book by Brandon Alinger (bring the book along if you’re going to visit). If you have the opportunity, I’d recommend going, even if you’ve seen the costumes before on previous Star Wars museum tours.