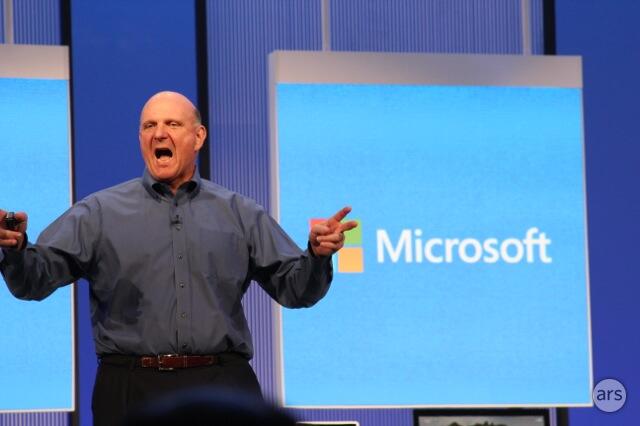

In this week’s Microsoftastic episode, Will, Norm, and Wes discuss BUILD 2013, Microsoft’s sudden change of heart surrounding Xbox One DRM, the truth about Windows 8.1, Tesla’s charging solution, the Makerbot sale, the Ouya’s launch, and a whole lot more. Enjoy!

The Talking Room: Adam Savage Interviews David Chang

Adam Savage presents a new series in which he invites friends for a chat in his home library. In this first episode, chef David Chang of Momofuku and Lucky Peach stops by to talk about the creative process of cooking, running his restaurants, and why MSG gets a bum rap. Two people, one room, one delightful conversation. We hope you enjoy it.

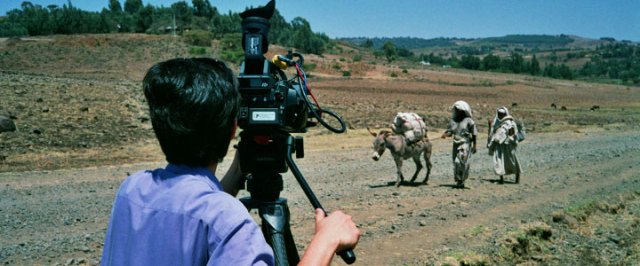

Documentaries Worth Watching – 6/25/2013

Stanley Kubrick Exhibit at The LACMA

Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Exhibit entrance

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Directors Chair

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Posters of Kubrick’s Films

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Posters of Kubrick’s Films

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Lolita Poster

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Posters of Kubrick’s Films

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick as a Photographer

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick’s Camera Lenses

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Dr. Strangelove

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: 2001: A Space Odyssey

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A Clockwork Orange

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: The Shining

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Eyes Wide Shut

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Eyes Wide Shut

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Eyes Wide Shut

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Eyes Wide Shut

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Spartacus

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Kubrick Exhibit

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Full Metal Jacket

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Full Metal Jacket

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: Full Metal Jacket

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

Photo Gallery: A.I.

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Stanley Kubrick Exhibit at The LACMA

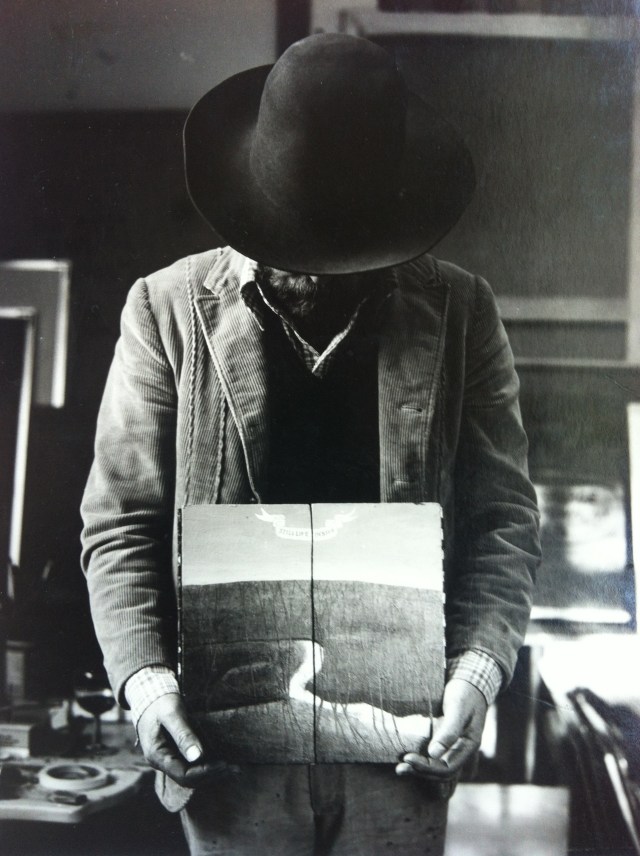

Photo Gallery: Barry Lyndon

Since last November, the Los Angeles County Museum of Art has been home to a special travelling exhibit documenting the late Stanley Kubrick’s movies, photographs, and personal projects. That exhibition concludes at the end of this month, so I drove down to LA this past weekend to see it before it moves to its next destination (it has been on tour all around the world since debuting in Germany in 2004). Among the items on display: iconic film props, production memorabilia, camera lenses Kubrick favored, and even early scripts with Kubrick’s handwritten annotations. Here are some of my photos from the exhibition. (A few photos NSFW)Mickey Mouse in Vietnam, By Lee Savage and Milton Glaser

Today as I was surfing Boingboing, I came across an amazing thing. A post by Cory Doctrow chronicling a moving antiwar film made years ago by Lee Savage and the designer (and his friend) Milton Glaser. Lee Savage was a painter and an animator and a director, and was always very proud of this film. Lee Savage was my father.

Milton’s people contacted me a few months ago to see if I had any copies of the film, but unfortunately I couldn’t locate any, which makes me doubly glad to see it up on YouTube, as I grew up seeing this film, and was sad at the prospect that it might have been inadvertently lost.

Milton did an interview with Buzzfeed recently about the film where they must have misinterpreted what he said because he seems to imply that Lee Savage died a couple of years after the Vietnam war. In point of fact, Lee Savage died nearly three decades later after a long and unfortunate battle with Alzheimer’s.

What a treat to see it again. Lee was a complicated, loving, generous, maddening, brilliant and difficult man/artist/father. I miss him every day.

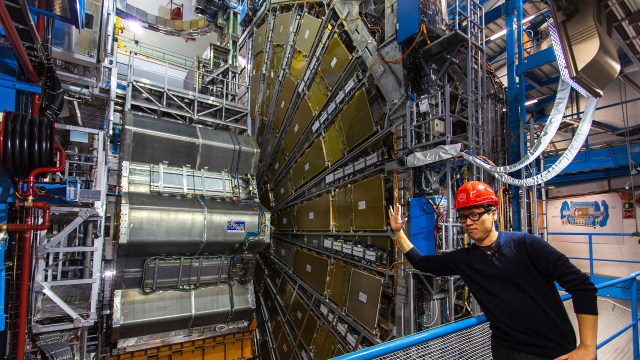

Tested at CERN: How The ATLAS Experiment Works

We chat with engineers at the ATLAS experiment at CERN to learn about the construction of particle detectors, how they work, and why they need giant 200-ton magnets. Super magnets, even!

The Volpin Project, Part 11: Prepping for Painting

Way back when I wrote my original outline for this series, I kind of put the cart before the horse and said I’d be discussing the process of painting the Needler prop before assembly. Then I read the closing for my last entry and noticed I said I’d be covering prep for paint first, which includes mounting points and drilling holes, before paint and weathering. Can you tell I don’t write for a living?

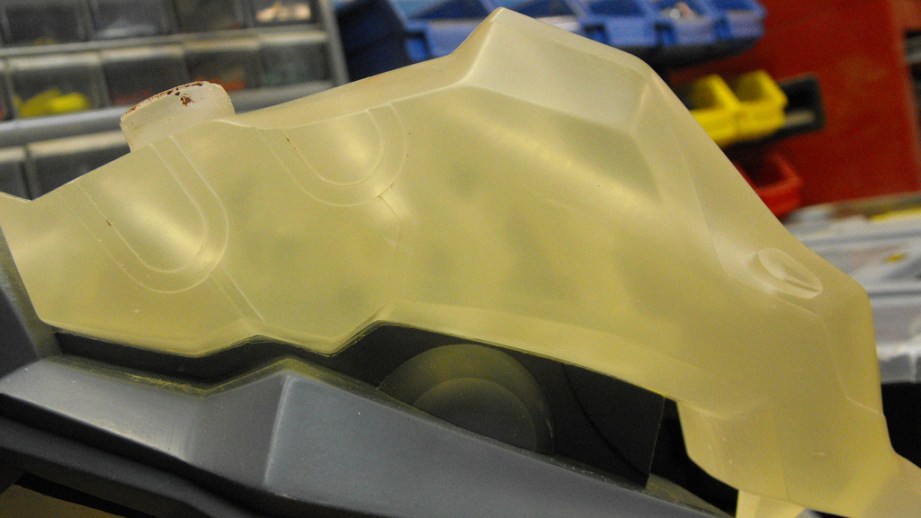

Today’s installment will be all about prepping your cast parts before going to paint. It’s important to have a plan for assembly of your prop before putting a shiny nice coat of paint on it, because as you’ll see in the steps below, it would be difficult to keep from marring a fancy paint job with all the drilling and cutting that needs to be done. When the individual parts of your project are still raw resin, you can afford to have a scrape here and there figuring out the best way for everything to fit together. Once things are painted, the last thing you want to do is fret over every bit of dust that might damage all your hard work.

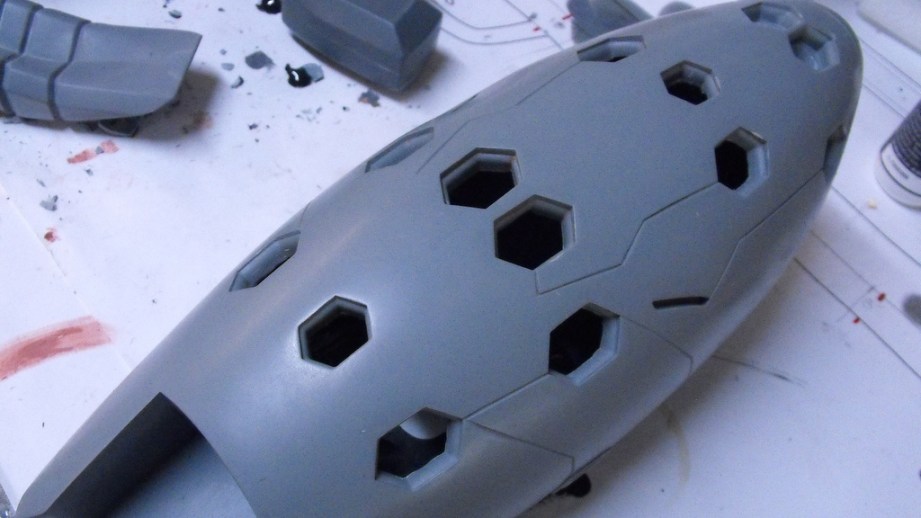

Since the upper casing will have the most chunks removed from it, I started there. The hexagonal cavities were actually pretty easy to remove with a small punch and a hammer. The needles will be epoxied into these areas once all the paint work is complete, and I want as much room in there to pull wires through and adjust the mounting angles of the needles.

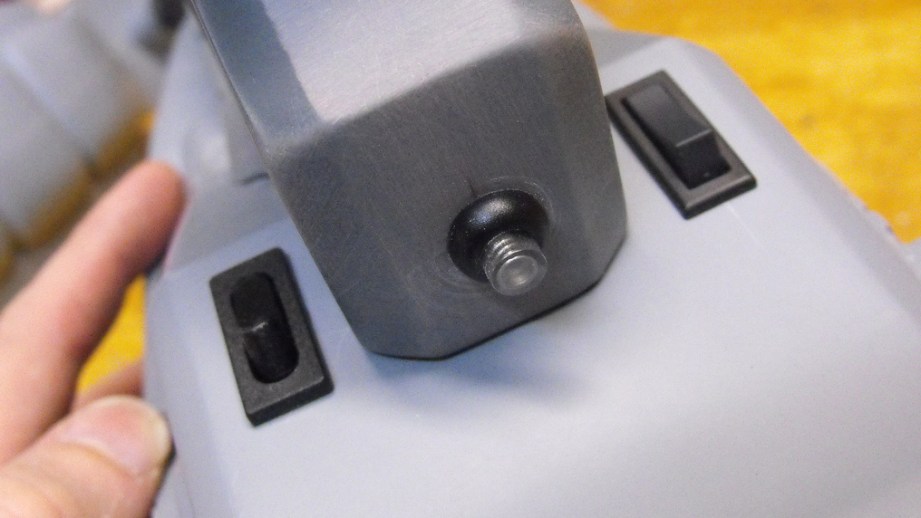

There were several other holes cut into the bottom of the casing as well. The large rectangular cutout will be for the main circuit board to fit into, and will be covered up by two other parts that mount here. At the rear is the speaker; nearly invisible once all the other parts are installed. To the front on the left and right of the handle mount are the on/off and semi/auto fire select switches. There’s also a hole in the handle mount area for wires to pass through from the trigger into the main body to connect to the audio circuit board. Make sure to take into account all of the wiring as well as mounting hardware at this stage!

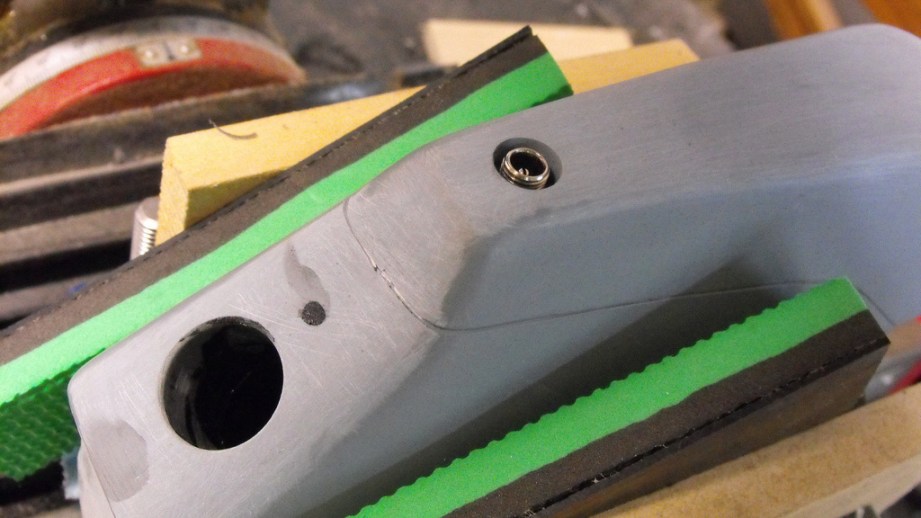

That small button will act as the trigger, and it’s been recessed into the handle with a hole routed through the top of the part into the main body. It also lights up blue!

At the rear, several magnets were countersunk into the vents and back plate to cover the three-AAA battery holder that will live in the upper casing. The magnets will hold these parts in place but will allow for easy removal when the batteries need to be changed, or if any maintenance needs to be done to the electronics later on in the life of the prop.

Since the Needler will be on display most of the time (theoretically), I’m making the circuit capable of running off a AC wall inverter instead of the internal batteries. The jack for this circuit has been countersunk into the lower casing at the furthest downward point of the gun to make sure the wire isn’t invasive while on display. Also, when holding the finished prop, your hand will cover this area so nobody will ever see the hole when the piece is in use.

Many people might choose to glue their props together, and a lot of my earlier pieces were held together mostly with superglue or epoxy. This can be tricky when assembling your piece as you’ll need to clamp the parts together while the glue cures, and often things can go together a little wonky.

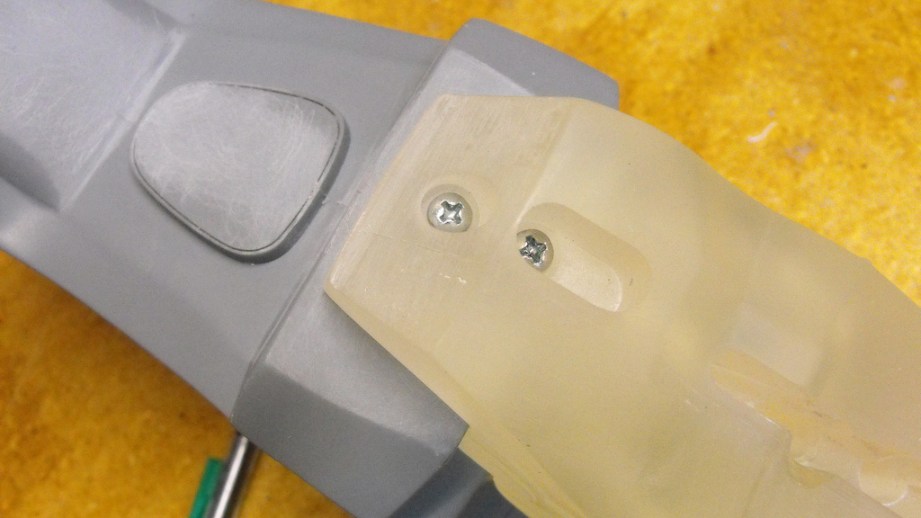

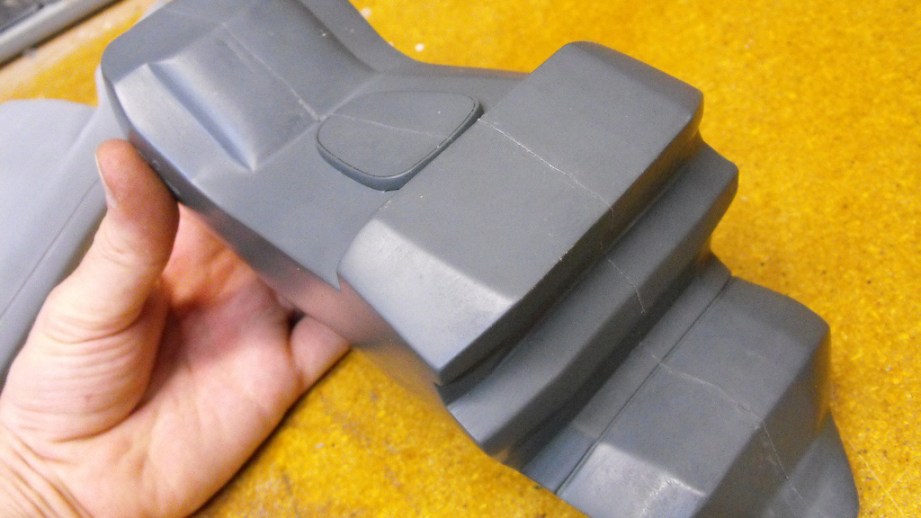

My preferred method now is to have as many pieces held together mechanically (read: screwed together) as possible. This may be reinforced with a glue joint as well during final assembly, but securing pieces together with bolts and screws ensures that every part goes together the same way each time it’s put together. Whenever possible make sure you have two mounting points–a single screw or post is really just a pivot point, and you’ll have to align it properly each time the parts are tightened down. With two posts and two holes, there’s only one way for the pieces to line up. The part below is the lower casing and the lower emitter.

Parts that will take more strain or weight will need hardware commensurate to their duties. The upper casing only has two mounting points to the rest of the gun, but will be one of the heaviest parts once complete. Because of this, two large threaded rods mount this part to the upper emitter and are secured with large washers and locknuts. While this might seem like overkill, nobody wants to crack open a completed prop to fix a stripped screw hole. If it’s worth doing, it’s worth overdoing.

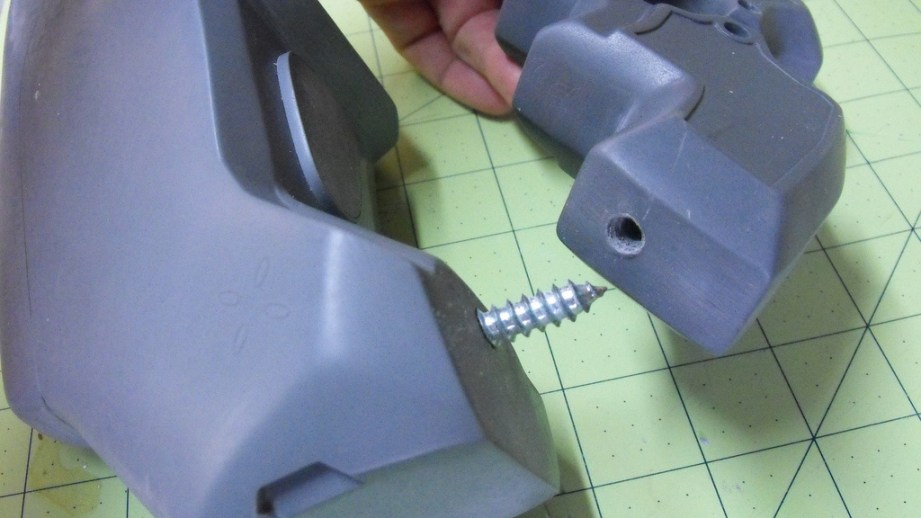

On that note, check out the nasty thing that holds the lower handle in place! I think this was a leftover from a flat pack furniture kit, but it’ll definitely get the job done. I couldn’t go with threaded rod here because the limited space in the lower casing wouldn’t let me fit a socket or wrench into the cavity to tighten a nut. I think 2″ of gnarly self tapping screw should hold things together pretty well though.

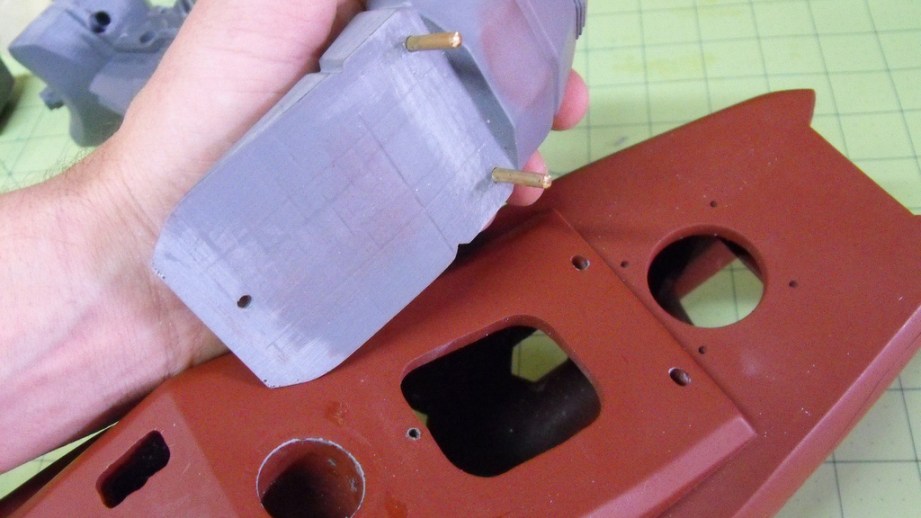

Smaller panels with less weight hanging off of them will require less dramatic solutions. For the lower detail bit on the upper casing, there’s only one small self tapping screw that will secure the part. The rear will be kept in alignment with two brass rods, and once all the parts are tightened up this piece won’t need any glue to be secure.